- Rendering Height:

- 5 m

- Power(W):

- 2.2kw

- Warranty:

- 1 Year

- After-sales Service Provided:

- Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, No after-sales service

- Condition:

- New

- Automatic Grade:

- Automatic

- Rendering Thickness:

- 20 mm

- Place of Origin:

- Shandong, China

- Brand Name:

- HW

- Dimension(L*W*H):

- 1350*800*500mm

- Weight:

- 240kg

- Certification:

- CE ISO1001

- Production Capacity:

- 800m2/day

- Voltage:

- 380/220

- Rendering width:

- 1000mm

- Frequency:

- 50HZ/60HZ

- Electricity Phase:

- Single Phase/ Three Phase

Packaging & Delivery

- Selling Units:

- Single item

- Single package size:

- 13.5X8X5 cm

- Single gross weight:

- 250.0 kg

- Package Type:

- Packing in wooden box

- Picture Example:

![package-img]()

- Lead Time:

Quantity(Set) 1 - 100 >100 Est. Time(days) 10 To be negotiated

Product Application

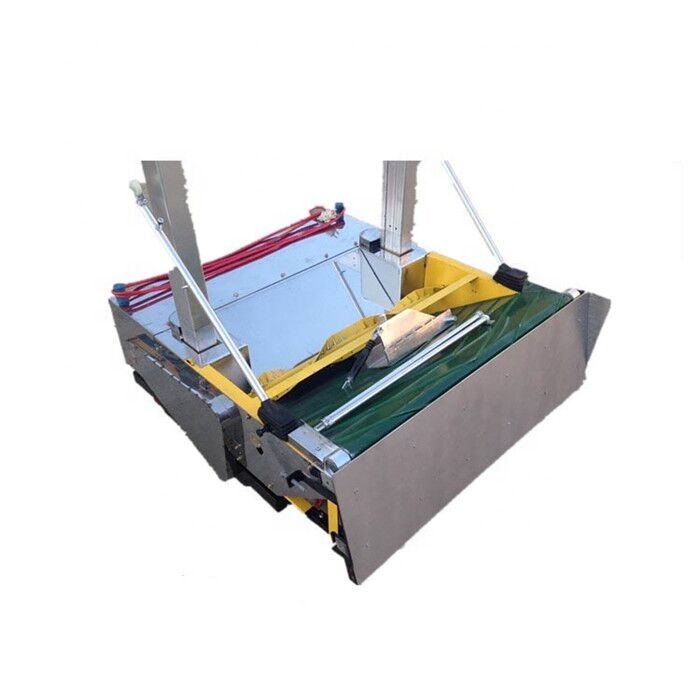

Automatic wall rendering machine is the ideal equipment for residential buildings, office buildings etc.It can plaster on cement wall, brick and concrete wall, hollow wall , light body brick, baking free brick wall etc.The rendering material could be lime, cement mortar , foam mortar, gypsum etc.The rendering thickness is no more than 3 cm and the height could be up to 5m. It could be adjust different thickness to suit each operation.

SPECIFICATIONS FOR PLASTERING MACHINE | ||||

Model | HW-60 | HW-S80 | HW-100 | HWS-100 |

Plastering trowel width | 60cm | 80cm | 80cm | 100cm |

Plastering height | Below 5 m | |||

Standard height | 3.6- | 2.8m-3.5m | 2.8m-3.5m | 2.8m-3.5m |

Plastering thickness | 2mm-30mm | |||

Plastering speed | 60square/h | |||

Voltage | 220V/380V | |||

Total power | 1.5kw | 2.2kw | ||

Quantity of vibrator | 2 | 3 | ||

Packing weight | 200kg | 240kg | 270kg | 270kg |

Packing Dimesion | 1050*700* | 800*800*1050 | 800*800*1050 | 80*850*1280 |

Wire rope | NO | YES | YES | NO |

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Machine Parts

1 .It can plaster the wall automatically and go up and down automatically.

2 .It can plastering by one-time.The thickness of the ash can be adjusted.

3 .Very easy and simple to operation

4 .It has large capacity hopper,you can put the ash/lime/gypsum in it one-time.

5 .Easy to operate.One or two person can operate.

6 .The quality is up to the international standard.Leakage protection device with high sensitivity, suitable for construction site safety and reliability .

Main Features

Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

High pressure double crank to control the die opening and closing.

Running in a high automatization and intellectualization,no pollution

Packaging | |

Size(mm) | 1140×680×700 |

Weight(kg) | 270 |

Packaging Details | composite material box |