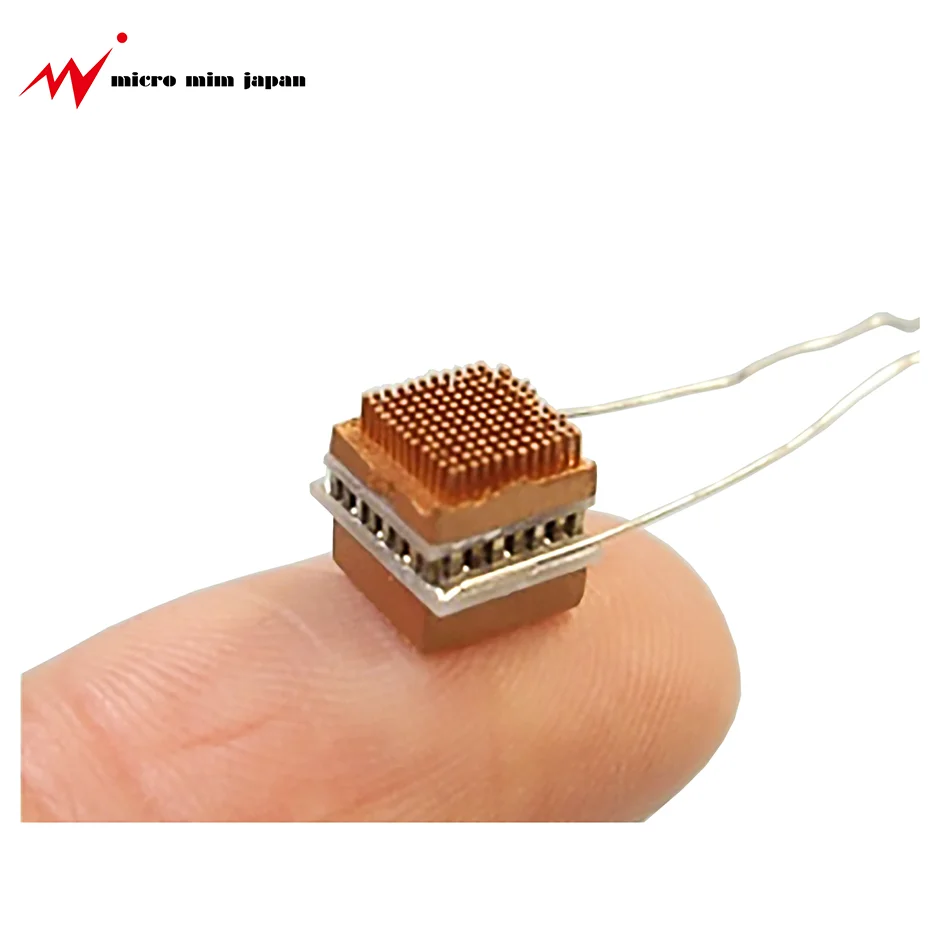

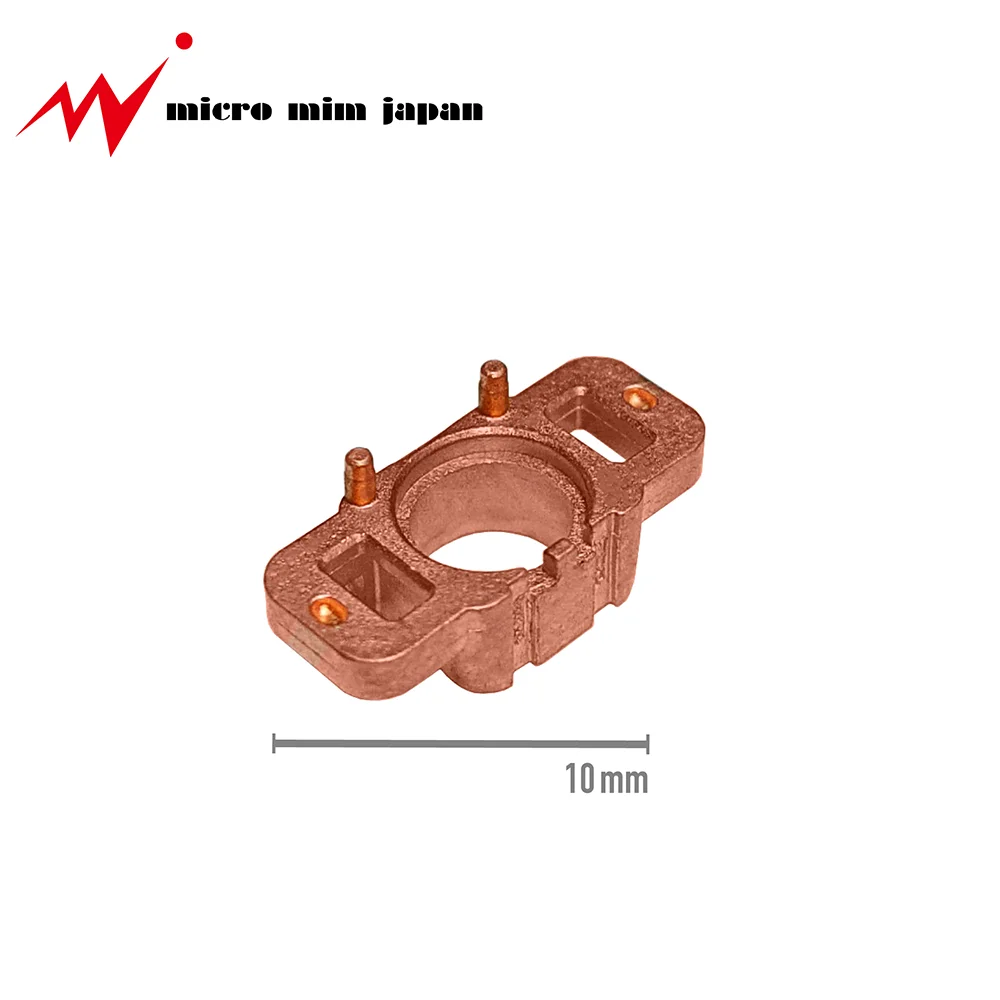

However, μ-MIM® technology optimised the binder system for copper production and realises the serial production of a copper product. Surely, the tight tolerance requirement or complicated hollow design will be accepted as other material μ-MIM® production.

Additionally, originally developed diamond-copper composite, extra high thermal conductivity, serial production is also available.