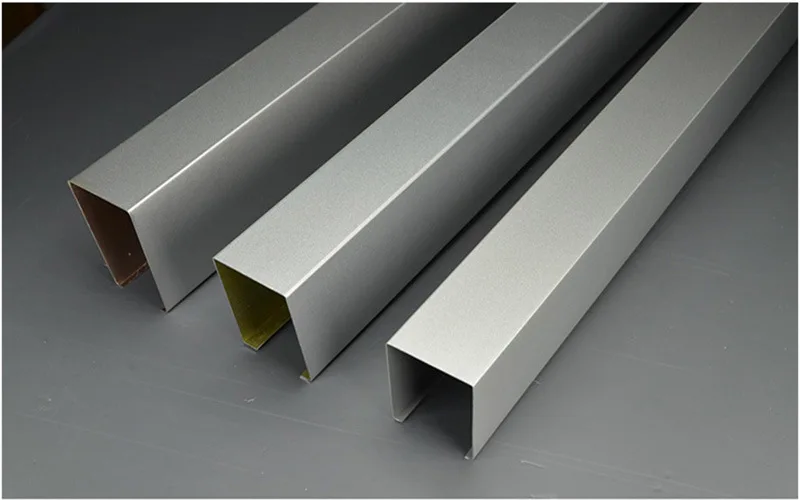

Product Description

Product Name | C-strip aluminum ceiling/other types |

Alloy | 1100,3003,3005,3105 |

Size | C100,C150,C200,C300mm |

Thickness | 0.6-1.4mm |

Surface Treatment | Powder coating, roll coating, Film covered |

Edge | Beveled /Square Edge |

Shape | Rectangle |

Packaging | Carton package |

Delivery Time | 15-20 days after receiving the deposit and confirm the details |

Payment | T/T, L/C, Western Union |

Recommend Products

Installation Instructions

ONE: galvanized steel wall panels; Hanging drywall

1Finish all the electrical, plumbing and insulation work that is necessary in yourwalls before you begin to install any drywall.

2. Mark the location of the wall studs on both the floor and ceiling, so you will be able to find them when you begin installing the sheet rock.

3.Lay a piece of scrap on the floor to raise the drywall off the floor (about 1/2 inch).

4.Starting in a corner, place the drywall onto the scrap and butt it into the corner. Ensure the other end of the sheet falls onto the center of a wall stud. (Sheets can be installed either vertically or horizontally. Most pros like to install it horizontally, since this means fewer joints to fill and the main seam is about four feet off the floor - a comfortable height to work at.)

5.Use drywall nails or your drywall gun and drywall screws to fasten the sheet in a couple of places to hold it. Now go back, and starting in the corner, push the drywall sheet tightly against the wall studs and fasten the sheet to all the studs it is covering. Place screws every 6 to 8 inches.

6.Continue around the perimeter of the room, butting sheets against each other, ensuring the ends are centered on wall studs, until the lower section is finished.

7.Measure from the top of the bottom sheet to where the top of the wall will be (this will be the height of the top piece of drywall). If the distance is less than 4 inches, cut the drywall sheet to the proper height and install it with the cut edge at the top.

8.Continue installing the top row all around the room.

TWO: galvanized steel wall panels; Cutting drywall

9.Measure and mark where you want to cut the drywall. Use a straight edge or a chalk line to join the marks. Always mark and cut on the front side of the panel.

10.Using a sharp utility knife, score deeply along the cut line.

11.Stand the panel on edge and snap the cut section back.

12.Finish by cutting through the paper on the back with your utility knife.

THREE: galvanized steel wall panels; Cutting around outlets

13.Measure from the edge of the outlet box to the edge of the panel and mark it. Now measure from the floor to both the top and bottom of the box and mark the panel. You should now have the outline of the box marked on the drywall.

14. Drill holes at the corners and then, using a drywall saw or a keyhole saw, cut the opening for the box.

FOUR: galvanized steel wall panels; Finishing drywall joints

15.Use a 6 inch taping knife to fill tapered joints (factory edge to factory edge) with a thin layer of joint compound (mud).

16.Center the drywall tape over the joint and run your knife along the tape, pushing it into the mud.

17.Cover with a thin layer of mud and let dry.

18. After the mud has dried (overnight), us a 12-inch taping knife to apply a 10-to-12-inch wide coat of mud, feathering or smoothing out the edges, and allow it to dry.

19.Apply the final coat of mud by thinning it slightly with some water and spreading a light coat over all the taped sections. Let it dry.

20.Sand the wall lightly in preparation for painting.

21.Follow a similar process (but using less mud on the first coat) for joints where cut edges butt against each other.

22.Finish inside corners by putting mud on both sides of the joint, folding the tape in half and then pressing it into the seam.

23.Attach metal corner beads to outside corners by nailing through the corner bead into the underlying stud and applying mud over the bead.

Products Description

Recommend Products

Product packaging

Application

Why Choose Us

Founded in 1999, Lanzhou Jintailong building materials Co., Ltd. is the first light steel keel and gypsum board manufacturer in Gansu Province. The company annually produces 3 million square meters of gypsum board and 3000 tons of light steel keel. The company has abundant capital and advanced production technology. At present, the products are mainly sold to five northwest provinces. The company has passed ISO9001-2000 quality management system certification. It has successively won the honorary titles of "contract abiding, credit abiding enterprise" and "honest private enterprise" in Baiyin City, Gansu Province. The company has 7 domestic advanced light steel keel production lines, 3 gypsum board production lines, complete production equipment, strong technical force, complete testing means and perfect management system. The production of "Talon" brand building gypsum board and light steel keel sell well in China, and are favored and praised by customers, "develop with credit, survive with quality" is the company's consistent business philosophy.

Certifications

FAQ

Q1:Are you Factory?

Yes we have factory in Songjiang and doing this business for over 10 years

Q2:Can we have discount?

Our price is only have small interest, we do not hope to waste your time in price ,Our factory mainly focus on quality control and offer ceiling solution. You get what you pay here.

Q3:What can we do for clients project?

We can offer professional building solution base on your request. make sure it is inbudget and the design will be modernized

Q4:What is the quality of our products?

We can offer many different kind of building materials,usually our ceiling quality can be 1-1.5years longer than other supplier do

Q5:Sample Free?

Yes, but freight collected.

Q6: Payment term?

T/T,L/C,Yes,by T/T,30% deposite before production,70% balance before delivery.

Q7: where is yout location?

We are located in Lanzhou,Gansu province.

Our service

1. If you email to us, we will get back to you within 12 hours, normally a lot sooner.

2. Make sure the size and thickness, you will get a more precise price.

3. We provide all kinds of specifications for your choise.

4. Estimated delivery may be affected by holidays, such as spring festival,national day.

5. Free sample is acceptalbe, just you should pay the delivery fees.

6. Free document: commercial invoice, packing list and certification of original.

7. The price of the models are subject to our final confirmation.

8. The product can be customized.)

2. Make sure the size and thickness, you will get a more precise price.

3. We provide all kinds of specifications for your choise.

4. Estimated delivery may be affected by holidays, such as spring festival,national day.

5. Free sample is acceptalbe, just you should pay the delivery fees.

6. Free document: commercial invoice, packing list and certification of original.

7. The price of the models are subject to our final confirmation.

8. The product can be customized.)