Equipment parameters:

1 | With glue ratio

| Any fixed ratio between 3:1 and 5:1 can be adjusted |

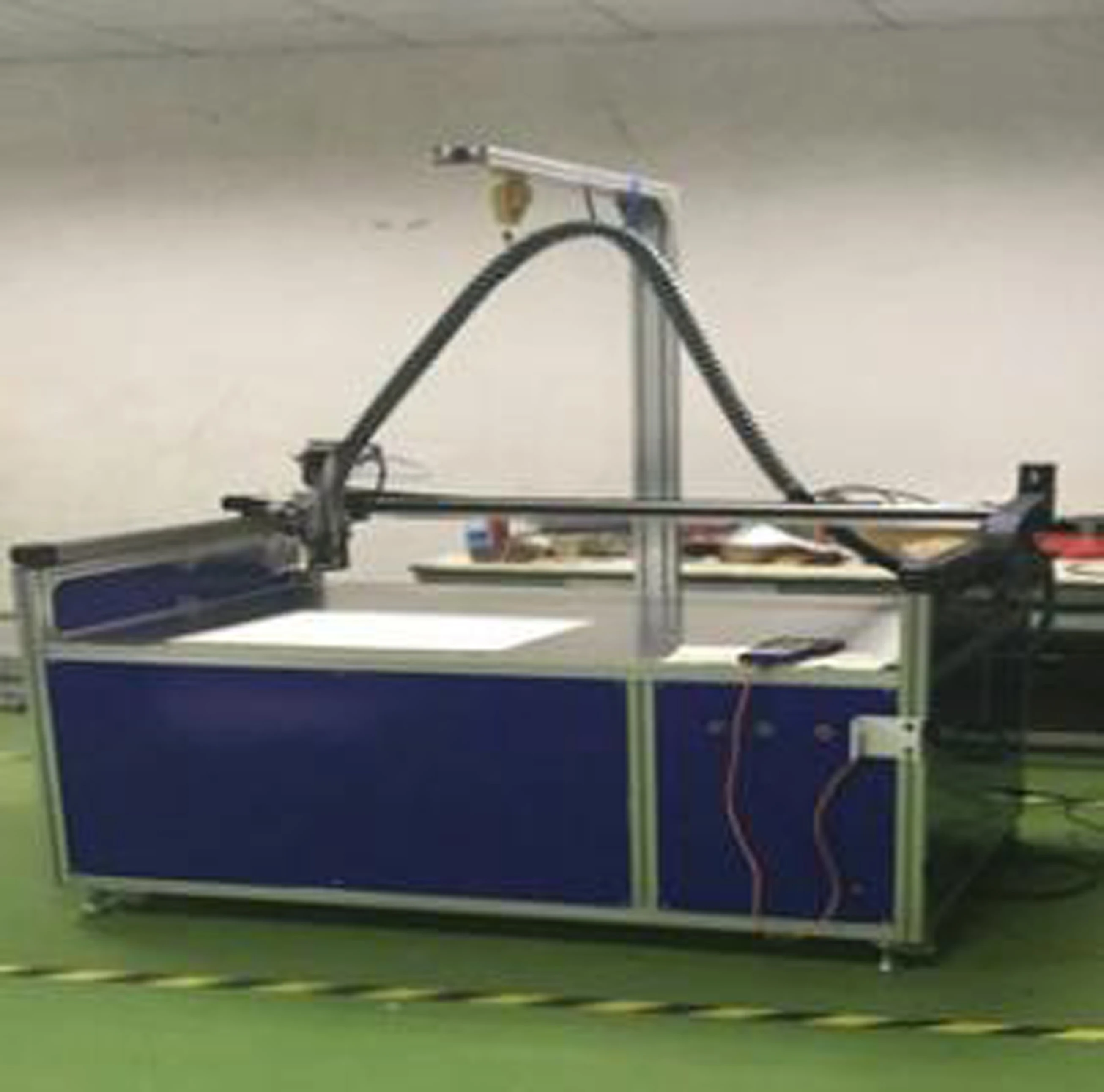

2 | Mixing way | The dynamic mixing |

3 | The machine schedule | The 680*680*30MM itinerary can be customized according to the actual needs of customers |

4 | countertops | Table 1050*900, effective working area 680*680mm |

5 | programmatically | Teach programming |

6 | Installation dimensions | 1220 * 1050 * 1500 mm |

7 | Main pump (A pump) | 9cc/ cc (Taiwan) screw pump |

8 | Attached pump (B pump) | 3.2cc/ cc (Taiwan) Gear Pump |

9 | For the adhesive power | Stepper motor |

10 | Plastic bucket capacity | A cylinder 25L with thermostat, B cylinder 10L |

11 | The plastic flow | 2-10 g/s |

12 | The rubber head | The standard single head |

13 | The input air pressure | 0.5-0.7 Mpa |

14 | The machine power | 1500 w. |

15 | The power supply voltage | AC220V plus or minus 10%, 50 to 60 hz |

Device configuration

1 | Control system | Sinjie PLC+ motion control card +7.2 inch kun Luntong touch screen

|

2 | The software system | Independent research and development, a domestic peer developed software anti - misoperation Function, prevent stay automatic stop function

|

3 | Stepper motor | YAKO original motor |

4 | The metering pump body | Taiwan precision adjustment wear resistant |

5 | By the system | Independent research and development manufacturing |

6 | Mixing device | Independent research and development manufacturing |

7 | Constant temperature device | Silica gel heater |

8 | Frame materials | A3 * 3 mm |

9 | Slide device | HIWIN track, Taiwan |

Equipment efficacy

1 | Friendly and simple operation interface | Anti-dumbing-type operation program design, simple operation, practical, Ordinary workers can learn all the operation methods in 5 minutes

|

2 | High-end imported electronic control system | Main electrical wiring, dust, anti - static, are up to foreign standards Relay omron. Adopt sinjie PLC Overload protection for all motors. High precision motion control system is adopted

|

3 | Glue quantity detection and feedback function | Part of rubber drum is equipped with low liquid level alarm function, timely remind glue supplement |

4 | Four times protective glue filtration | Filter protection measures to reduce the failure rate of mechanical pump body, Prevent impurities from flowing into the glue pipe

|

5 | Oversized countertop | The machine is divided into left and right two pieces, and two plates of materials are put respectively. The machine operates automatically and continuously. Have more efficiency

|

6 | The equipment runs more smoothly | The whole frame adopts super thick and stable material, which can effectively solve the high speed of the machine When the movement of the body jitter, improve production stability and precision

|

7 | High precision mechanical pump body | Precision adjustment wear resistant |

8 | Fully automatic mechanical stirring | The mixing of AB glue adopts dynamic and mechanical stirring to ensure the authenticity of AB glue Meaning of mixing, completely eliminate glue dry, dry glue uneven phenomenon

|

9 | High precision operation | Adopt double layer linear sliding track and high precision balance block to ensure the working accuracy |

Characteristics of three-axis motion irrigation:

1.Simple and convenient operation: touch screen display operation;Full Chinese interface, record, display and alarm of various parameters;According to each product to provide the corresponding fixture, workers training simple, save training time and training costs;

2. Precise control of glue quantity: all key components are imported products, which can ensure high speed and precision and meet the requirements of high reliability under automatic production conditions.

Main features of glue pouring machine:

1. Glue dispensing, glue pouring integration, automatic operation, one machine to achieve two functions.

2, the proportion setting adjustment, the amount of glue can be adjusted.Ready to use at any time, the ratio of high precision, according to the need ratio, save glue.

3, easy to operate, simple program editing, easy to disassemble and convenient, directly put the two kinds of glue A and B into two corresponding buckets, filling the glue, workers just need to press the start switch.

4. According to the performance of glue, barrel A has A constant temperature device, barrel B has good sealing ability to prevent volatilization, and liquid level sensing device.

When the glue is lower than this level, it will automatically alarm and add the corresponding glue

5. It is convenient to clean. For the mixing part of A and B rubber, there is only the mixing pipe at the rubber outlet, so the only mixing pipe is for the cleaning part.

The other parts do not need to be cleaned. If you do not pour glue after work or stop for a period of time, you just need to remove the mixing tube and clean it. The consumable material is only the mixing tube.

Characteristics of three-axis motion irrigation:

1.Simple and convenient operation: touch screen display operation;Full Chinese interface, record, display and alarm of various parameters;According to each product to provide the corresponding fixture, workers training simple, save training time and training costs;

2. Precise control of glue quantity: all key components are imported products, which can ensure high speed and precision and meet the requirements of high reliability under automatic production conditions.