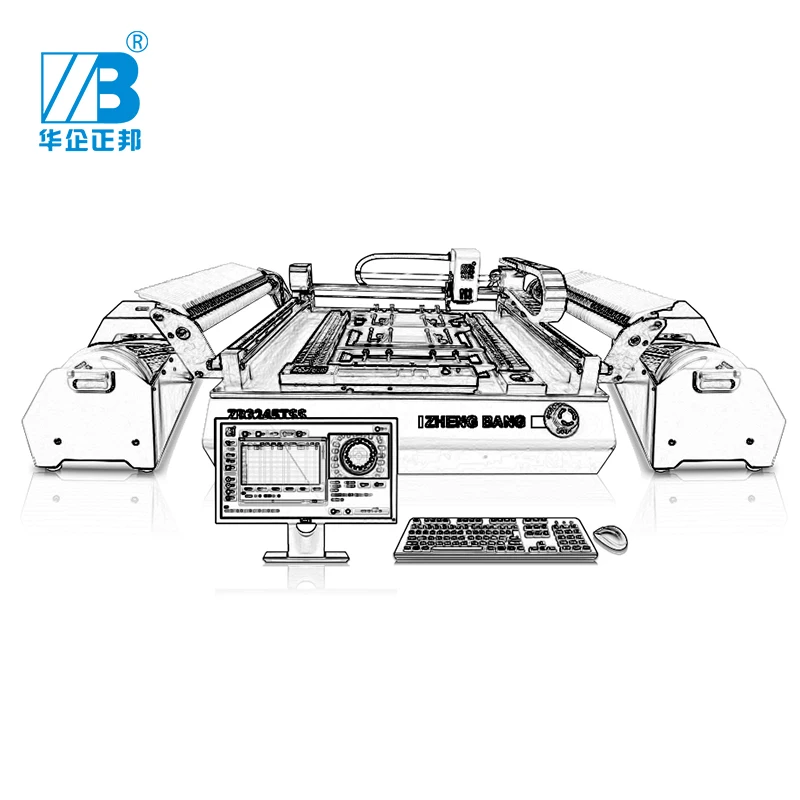

Smt Desktop Automatic Pcb Led Production Mini Low Cost Fast Speed Small 2 Heads Placement Light Pick And Place Machine

------Introduction------

Application:Prototyping Machine, Small Production, LAB work, D&R, Education.

Brief Introduction: Machine is customized for small production and prototyping business, with self-designed operating system for developers.

Service:

Ø 24-hours consultant for operating and marketing.

Ø Professional after sell service.

2. Product specifications:

| System | Items | Content |

| Mounting System | Mounting head number | 2 pieces |

| Mounting accuracy | 0.025mm | |

| Mounting angle | 0~360° | |

| Theoretical Velocity | 8000pcs/hour | |

| Normal mounting | 5500pcs/hour | |

| Visual Mounting | 4500pcs/hour | |

| Nozzle type | Juki series nozzle | |

| Elements for mounting | RC (0402, 0603, 0805, 1206, etc) | |

| LED lamp (0603, 0805, 3014, 5050, etc) | ||

| Chip (SOT, SOP, QFN, BGA, etc) | ||

| Substrate | Substrate minimum size | 10×10mm |

| Substrate maximum size (no tray) | 320×450mm | |

| Substrate maximum size (with tray) | 320×220mm | |

| Substrate thickness | ≤2mm | |

| Substrate warp allowed value | <1mm | |

| Feeder | 8mm | 40pcs |

| 12mm | 8pcs | |

| 16mm | 4pcs | |

| 24mm | 2pc | |

| Preposition IC material level | 10pcs | |

| Postposition IC tray | 1pc | |

| Tubular materials feeder | Zhengbang dedicated Five tubular materials feeder one (optional) | |

| X, Y, Z axis | X, Y axis moving range | 430*530mm |

| Z axis moving range | 10mm | |

| Z axis rotation angle | 0~360° | |

| Visual system | independent research and development | |

| Visual System | Visual camera | CCD high-definition camera |

| Visual quantity | 4 (2 small camera 1 big camera, 1 up camera) | |

| Identification ability | MAX.20*20mm | |

| Control System | PC system | Microsoft WIN7 |

| Operational software | independent research and development | |

| Compatible file format | CSV, TXT. format file | |

| Programming mode | Support online and offline | |

| Pressure | 0.4 MPa (The built-in pump) | |

| Basic Parameter | Vacuity degree | MINUS 92KPA |

| Power | 150W | |

| Power supply | AC220V 50HZ | |

| Main engine outline size | L 830*W 730* H375 mm | |

| Materials feeder outline size | L 235*W 700*H 245 mm | |

| Net weight | 56kg | |

| Gross weight | 83kg | |

| Outline package size | 1190*850*560mm |

Factory infomation:

Exhibition:

Packing:

11. SMT series related products:

JUKI smt pick and place machine, smt pick and place machine, pick and place, led mounter machine, led pick and place

13. Notes

1.Machines need keeping away from the humid environment and dust, or which will get on electrical shock and fire.

2.Machines need lying stable platform, or which the shake may lead to reduce the precision and even turn over and personal injury.

3.Don’t dismounting the machines casually, or the machine may be broken.

4.Don’t touch the optical axis and the mounting head, or which may damage the machine and hurt yourselves.

5.Make sure the machine engine accordance with the requirements of the standard machine and make sure lie on the ground very well.

6.Make sure the machine away from the inflammables and explosives to avoid the fire and getting the electric shock.

7.Take the small machine parts like suction nozzle at the place where the babies can’t touch.

8.Don’t take the pulling needle stretch out for too long time, or the pulling needle will be broken.

9.Don’t take the machine in the Sun or the highlight directly, or which will reduce the machine precision and even broke the machine.

10.Please kindly contact us if any other questions.

Plywood case and film or as custom require.

------FAQ------

1. In case the machine breaks down, where can I find the spare parts?

Once your machine have the problem, please contact me or leave a message to my email . I will forward your message to our engineers and within 24 hours we will arrange inspection for your machine remotely.

If it needs replacing any spare parts, we will send it to you directly by TNT,DHL or others.

We have the technical teams in some area. If you need local service, you have to cover the travel expenses, labor cost. They will provide service for you directly.

The machine will be packed with some spare parts according to our experience.

2. Payment term?

We accept:T/T, VISA, PAYPAL, WEST UNION, BANK TRANSFER, ONLINE BANK PAYMENT

3. What about the lead time?

1~2 weeks after we received the payment, we will start the delivery. For customized order, it depends on practical situation.

4. How about the Training ?

We provide the online remote training service, and we will offer you the operating video and manual for users’ repeatedly learning.

5. What’s the applicative component size for this machine?

Minimum component size: 0402.

maximum size: lead pitch no more than 0.5mm, such as QFP100.

Components height:<5mm.

6.Which nozzle suit for the component?

Machine used YAHAMA series nozzle.

size 500 nozzle:1005,1608,2012.component minimum width:0.45mm to 1.45mm.

Size 501 nozzle:0603,0402.component minimum width :below 0.45mm

Size 502 nozzle:0805,1005,1608,2012.component minimum width:0.45mm to 0.75mm.

Size 503 nozzle:0805,1206,1608,2012.component minimum width:0.75mm to 1.45mm.

Size 504 nozzle:2012,3216,SOT23.component minimum width:1.1mm to 2.5mm.

Size 505 nozzle:component minimum width:2.5mm to 4mm.

Size 506 nozzle:component minimum width:4mm to 7mm.

smt pick and place machine, pick and place, led mounter machine, led pick and place machine, smt chip mounter,mounter, smt mounter,chip mounter, charger making machine, laptop making machine,

pcb assembly line, led tube light assembly machine, led&smd product line, led&smd, semi auto production line, full-auto production line, automatic production smt line, auto smt line, smt automatic production line, smd pick & place machine, SMT assembly line for small and medium batches, PCB fabrication, pick & place machine and Reflow Oven, pick and place for electronic components, Desktop smd pick and place machine,