We would like to organize 6 popular injection molding materials, that often used for electronic product enclosure, and plastic cases. The information would be a good reference for product designers or mechanical engineers, when they’re going to develop a new product.

The materials we are going to discuss are: PP, HIPS, ABS, PC, ABS+PC, and ASA.

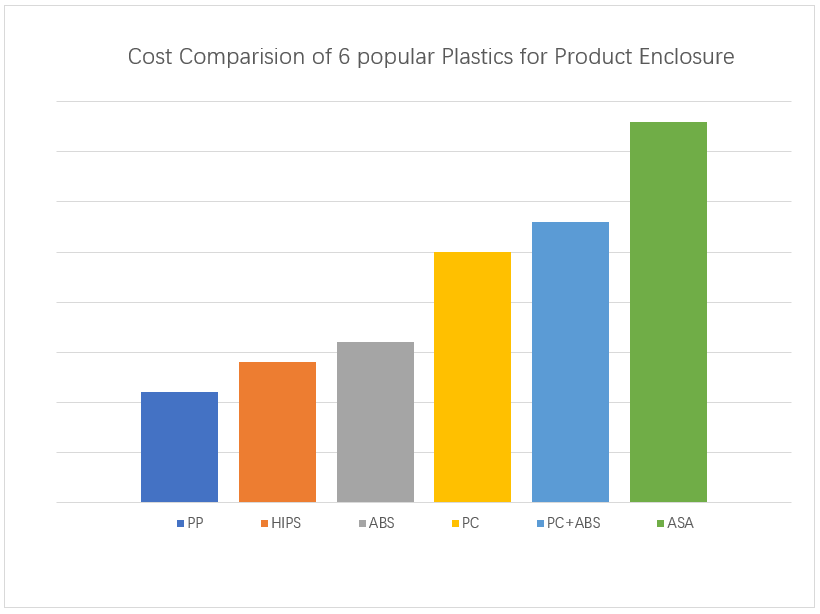

At the beginning, we would like to list the cost comparison of the 6 materials.

It can help us having a quick guide line when preparing a project schedule at early stage.

What we would like to mentioned about here is that, HIPS is often use as an alternative of ABS. But for rapid tooling, we prefer using ABS, as their unit prices are pretty close, and there is no much difference at low volume production. While HIPS is not as bright as ABS, and not as tough as ABS.

Besides the cost, what we concern about more at enclosures, would be the strength, cosmetic, applications at different environments, and typical usage. We listed their most famous property here:

1) PP is very famous for its folding property, often using at case with integral hinge;

2) PC is very good at strength and its clear, and also bad flowing ability. A very important component for bullet-proof glass.

3) ABS, is the most widely used one at product enclosure and cases.

4) PC+ABS, a compromising choice between PC and ABS, because of their strength and flowing ability.

5) ASA is very famous for its out-door usage, because of its weather resistance.

6) HIPS, often used as ABS alternative at high volume production, for cost saving.

In general, we also put their advantages, disadvantages and general applications in a same form:

Full Name | Advantages | Disadvantage | Application Examples | |

PP | Polypropylene | Low cost, good at toughness, very good for hinge | Not strong as other materials, high shrinkage. | Trash Bins, Glasses Cases, Covers with hinge |

HIPS | High-Impact Polystyrene | Alternative of ABS, for cost saving. | No as bright, as tough as ABS. | Trash Bins, cases, covers and etc. |

ABS | Acrylonitrile Butadiene Styrene | Very good general mechanical property. Most widely used. | n/a | Bins, Most Cases, Cover, most frequent used engineering resin. |

PC | Polycarbonate

| Best strength in 6 materials, High clear | High cost, bad flowing, not tough as ABS | Defensing Covers, Clear Windows |

PC+ABS | Polycarbonate + Acrylonitrile Butadiene Styrene | Strength between ABS and PC. A choice for higher strength but with material flow concern. | High cost | Most covers, chassis, cases, a comprising choice between strength and toughness. |

ASA | Acrylonitrile Styrene Acrylate | Weather resistant; static-free, | High cost, not bright as ABS | Bicycle Light, Mountaineering products, Forest Monitors. |

Lastly a general property comparison in density and shrinkage.

Most of the materials are non-crystalline ones, except PP, which is crystalline material.

The other 5 materials have a very closed material shrinkage, around 1.005, which is good for product development. If multi material trials need, because of cost saving, strength testing, weather-resistant testing and etc., they can share one proto mold, as their dimension will be very closed and should not affect general assembly.

Full Name | Density | Shrinkage | Remark | |

PP | Polypropylene | 0.91 | 1.018 | Crystalline resin |

HIPS | High Impact Polystyrene | 1.1 | 1.005 | Non-crystalline, closed shrinkage, good for material trials |

ABS | Acrylonitrile Butadiene Styrene Plastic | 1.07 | 1.005 | |

PC | Polycarbonate | 1.15 | 1.005 | |

PC+ABS | Polycarbonate + Acrylonitrile Butadiene Styrene | 1.25 | 1.005 | |

ASA | Acrylonitrile Styrene Acrylate | 1.07 | 1.005 |

Just be notification that the information here is for the general grades, they would be slight variance in different bands. The materials also can be in special usage after adding specific additives, for example in fire retardant, UV resistance, food grade and etc.

Dank Mold will keep sharing more tooling and injection molding knowledge at our website www.dankemold.com, in a more and more organizing and easy-understanding manner.

Should you developing at a consumer product enclosures/cases, or any material enquiries of injection molding, just email us via info@dankemold.com. We will response in 12 hours.