7 series of aluminum classification and application fields

According to the different metal elements contained in aluminum, aluminum can be divided into 9 series. Here are 7 series of aluminum:

7 Series aluminum features:

Mainly zinc, but sometimes a small amount of magnesium, copper added.

The superhard aluminum alloy contains zinc, lead, magnesium and copper alloys nearly as hard as steel.

The extrusion speed is slower than 6 series alloy, and the welding performance is better.

The 7005 and 7075 are the highest grades in the 7 series and can be strengthened by heat treatment.

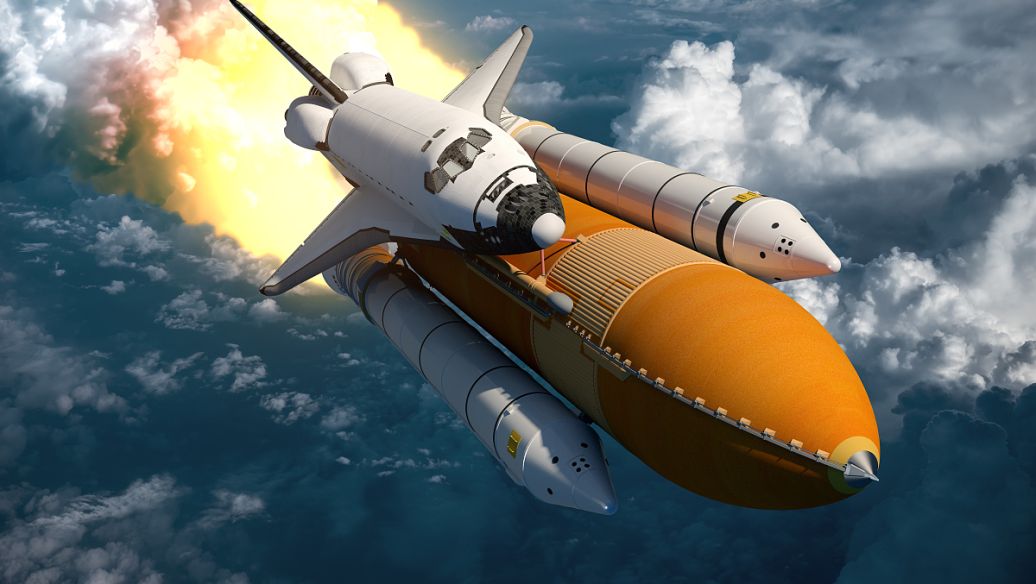

Application: aviation (aircraft load-bearing components, landing gear), rockets, propellers, aerospace.

7005 extruded materials, used to manufacture welded structures with high fracture toughness and high strength, such as trusses, rods and containers of transportation vehicles;

Large heat exchangers and parts that cannot be fixed after welding;

It can also be used to make sports equipment such as tennis rackets and softball bats

7039 Refrigerated containers, cryogenic equipment and storage tanks, fire pressure equipment, military equipment, armor plate, missile equipment

The 7049 is used to forge parts with the same static strength as the 7079-T6 alloy but with high stress corrosion cracking resistance, such as aircraft and missile parts -- landing gear hydraulic cylinders and extrusion parts.

The fatigue performance of the parts is approximately equal to that of the 7075-T6 alloy with slightly higher toughness

Medium thick plates, extrusions, free forgings and die forgings for aircraft structural parts.

The requirements for the manufacture of such parts are: high resistance to exfoliation corrosion, stress corrosion cracking, fracture toughness and fatigue resistance

7072 air conditioner aluminum foil and extra-thin strip;

Coating layer of alloy plates and pipes of 2219, 3003, 3004, 5050, 5052, 5154, 6061, 7075, 7475 and 7178

It is used to manufacture high-stress structural parts and moulds with high strength and strong corrosion resistance

High strength structure for forging aircraft.

T736 material has good comprehensive properties, that is, high strength, resistance to exfoliation corrosion and stress corrosion cracking, fracture toughness and fatigue strength

7178 Parts and components for the manufacture of aerospace vehicles requiring high compressive yield strength

Aluminized and unaluminized panels, wing frames, girder, etc. for the fuselage 7475.

Other parts that have high strength and high fracture toughness

7A04 skin, screws, and bearing elements such as girder, diaphragms, wing ribs, landing gear, etc.