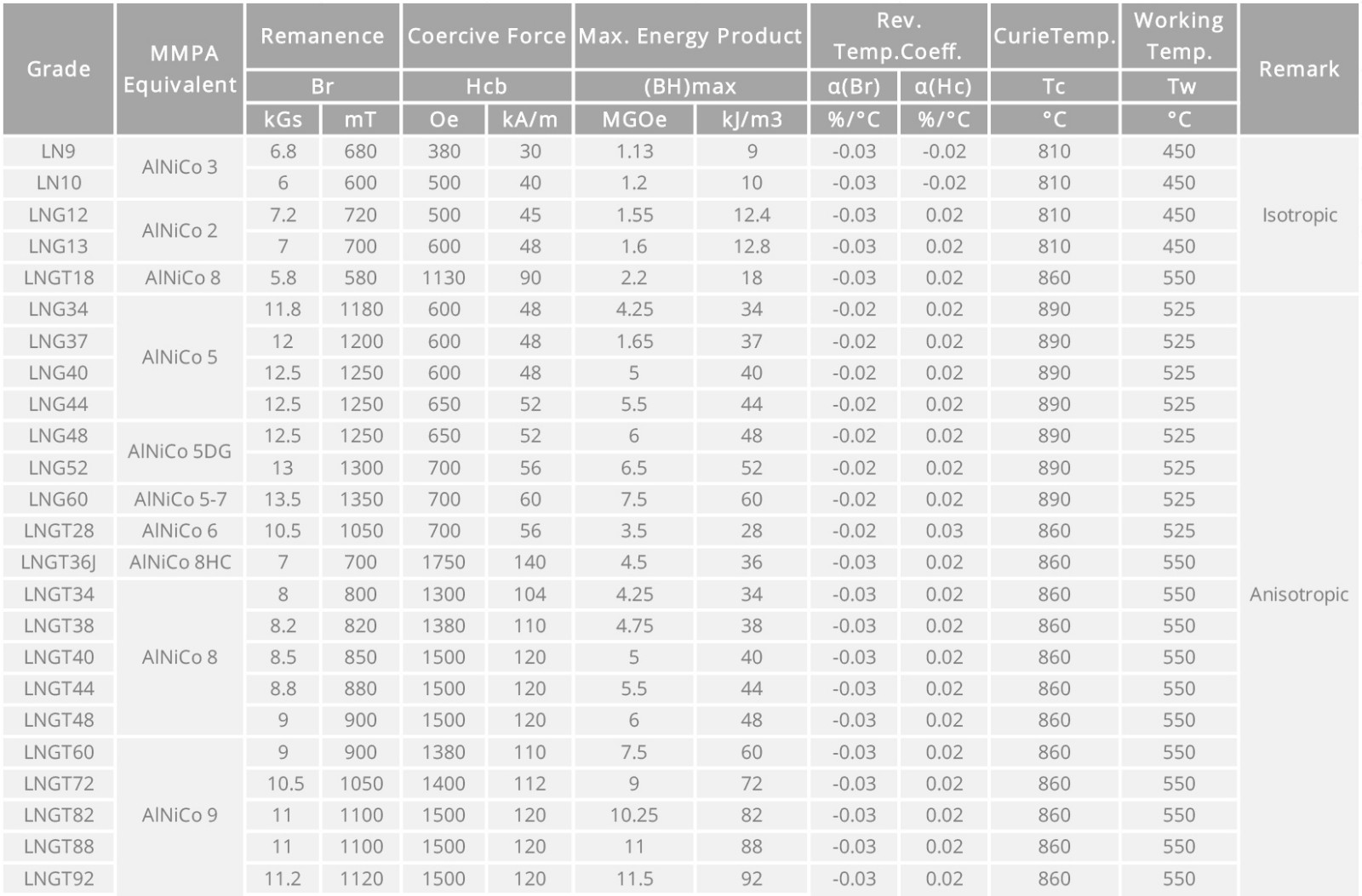

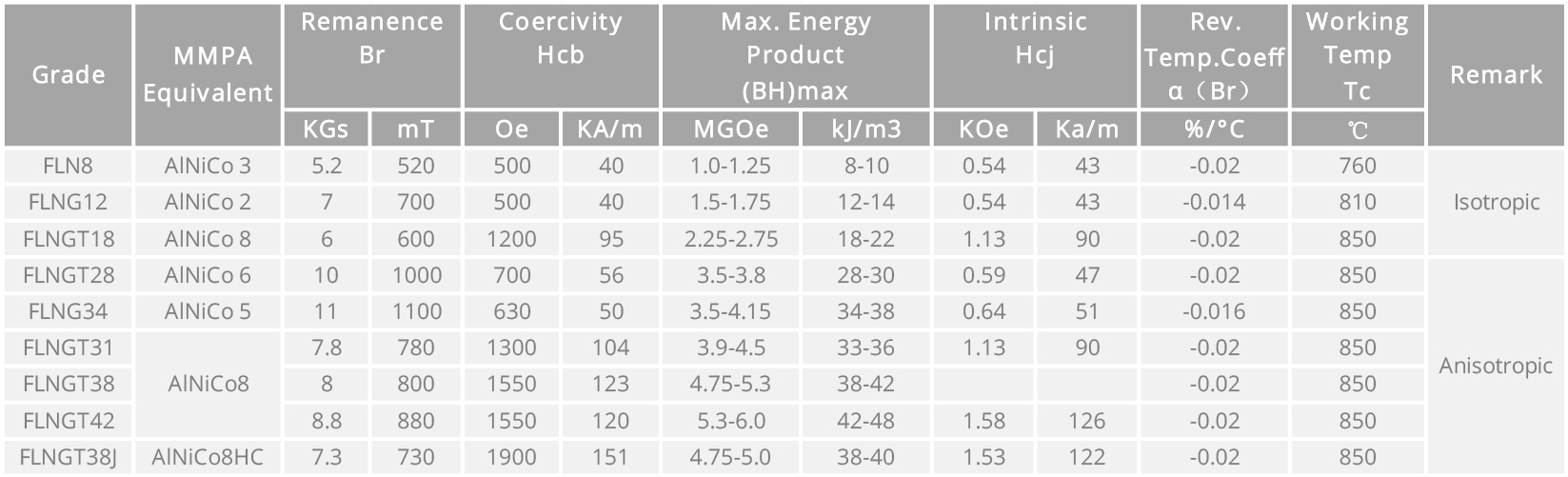

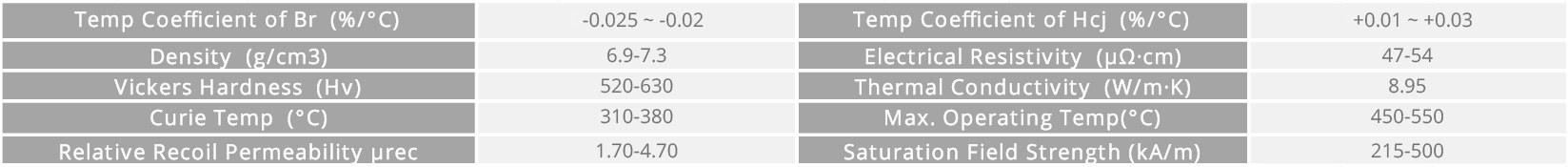

AlNiCo (Aluminium, Nickel, Cobalt and Iron alloy) is obtained by casting process, shaped in cheap phenolic resin sand moulds. It is the oldest and most stable magnetic material, with temperature coefficients of -0,03%/°C (Br) and -0,02%/°C (HcJ). It can operate in environments up to 500 °C with a very good resistance against corrosion, therefore coatings are seldom required. For multi-pole magnetizing patterns isotropic material is available. Higher energy anisotropy is obtained by external coils orientation during the thermal treatment.

Because Alnico magnets are coarse-grained, hard and brittle, conventional machining such as drilling is not possible, however, finished surfaces may be obtained by grinding.

A unique characteristic of AlNiCo is its very high residual induction vs. a very low coercivity, therefore in most applications it can be effectively used by magnetizing after assembly in the magnetic circuit, and it is specially recommended in applications where only a temporary demagnetization is required (magnetic chucks, lifters...). For small sized models, due to the typical porosity of the casting process, sintered versions (ALSINT) are available upon request.