Winding is one of the most important operation, which is mainly occurred in spinning section. Besides, it is also important in fabric manufacturing. In fabric manufacturing, directly winding is not so much important, but rewinding is so important. The creation of large yarn packages that can be easily unwound, is called winding. This makes using the yarn on subsequent machines both easier and more economical.

|

| Winding Section |

Winding is more than just transferring yarn from one package to another. Further functions of winding are to check the yarn and to eliminate any faults found.

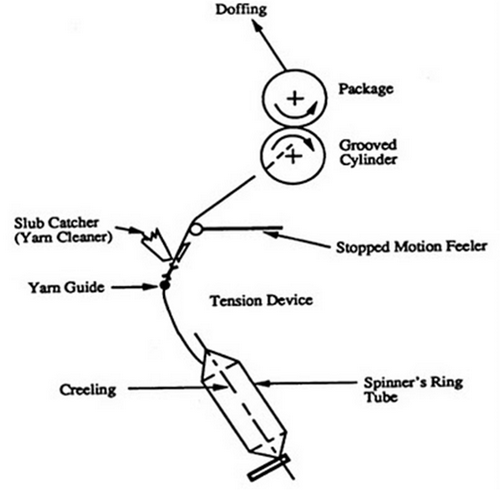

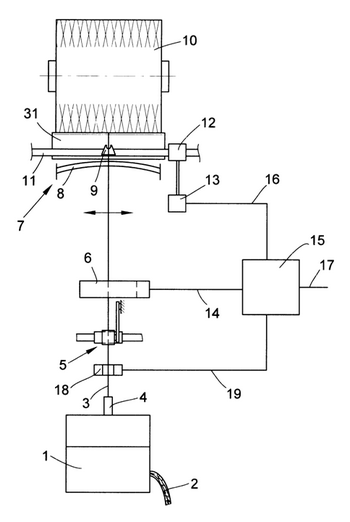

A basic diagram of winding m/c:

|

| A basic diagram of winding m/c |

Creeling: Creeling is the removing of empty package and placement of the full package, in the feed region of the machine, ready to be unwound as part of the transfer process.

Piecing: Piecing is the process of finding the ends of the packages and connecting them

Doffing: Doffing is the process of removing the full package and placement of the empty package, in the delivery region of the machine, ready to receive yarn as part of the transfer process.

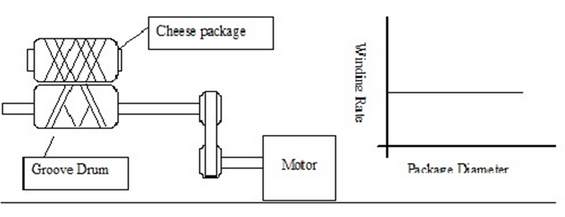

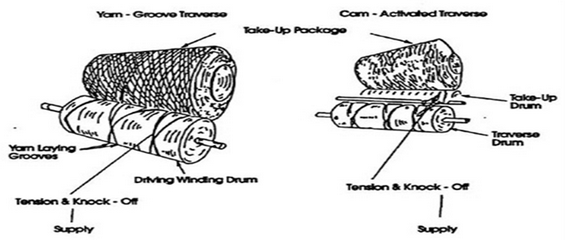

Surface contact driving

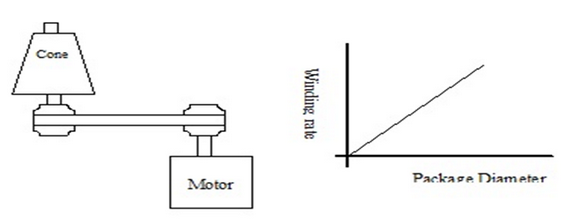

Direct package driving at constant speed

Direct package driving at variable speed

In this process the groove drum is rotated by the motor. The drum is in contact with the package so as the drum rotates the package also rotates. The grooves in the drum provide the traversing motion for the yarn. Here the winding rate stays constant as package diameter increases.

|

| Surface contact driving |

In this system the yarn package is placed in a spindle and the spindle is rotated with the motor. Therefore the package gets motion directly from motor. The package gets angular motion and the yarn take up rate is directly proportional to package diameter.

|

| Direct package driving at constant speed |

In this system the yarn package is placed in a spindle and the spindle is rotated with the motor. Therefore the package gets motion directly from motor. Here the rotational speed of package is varied inversely to package diameter to keep winding speed constant.

|

| Direct package driving at variable speed |

Reciprocating yarn guide

|

| Reciprocating yarn guide |

|

| Reciprocating yarn guide passage |

|

| Grooved Drum |

By precision winding successive coils of yarn are laid close together in a parallel or near parallel manner. By this process it is possible to produce very dense package with maximum amount of yarn stored in a given volume.

Features

Package are wound with a reciprocating traverse

Patterning and rubbing causes damage of packages

Package contains more yarn

Package is less stable

The package is hard and compact

The package is dense

Rate of unwinding of package is low and the process of unwinding is hard

The unwound coil is arranged in a parallel or near parallel manner

By this type of winding the package is formed by a single thread which is laid on the package at appreciable helix angle so that the layers cross one another and give stability to the package. The packages formed by this type of winding are less dense but is more stable.

Features

Only one coil is used to make this packages

Cross winding technique is used

The package density is low

Minimum number of yarn is wound

The package formed is soft and less compact

The stability is high

Flanges are not required

The rate of unwinding is high and the process is easy

The packages formed have low density

Winding Efficiency: [Actual production / Calculated production] * 100%

Winding efficiency depends on the following factors:

Spindle or drum speed: The higher the speed the more is the winding efficiency

Yarn Count: Yarn count is proportional to winding efficiency

Yarn quality: If yarn quality increases then winding efficiency increases

Worker efficiency: The more efficient the work is the more efficient the winding will be.

Humidity: Humidity is reciprocal or inversely proportional to winding efficiency.

Work load per worker: If the work load on each worker is less then efficiency of winding will be more.

Maintenance and over hauling: If the maintenance and over hauling of the machine is not correct then efficiency of winding will decrease.

Power failure: If power failure rate increases the winding efficiency will decrease.

Creeling time: The more the creeling time the less is the efficiency.

Doffing time: The more the doffing time the less is the efficiency.

Capacity utilization: When capacity utilization decreases then efficiency increases.