A. Concept Of Permeable Concrete

Permeable concrete is a kind of porous concrete, also known as porous concrete, sand - free concrete, permeable floor.

It is a kind of porous lightweight concrete made of aggregate, cement, reinforcing agent and water. It contains no fine aggregate.

Commonly used pervious concrete according to the composition of the material, there are cement pervious concrete, asphalt pervious concrete. According to the appearance of pervious concrete is divided into ordinary pervious concrete, color pervious concrete and exposed material pervious concrete.

B. Preparation And Conditions

2.1 On-Site Preparation

Preparatory work before pervious concrete construction: refers to the pervious concrete construction before the completion of each process, has passed

Acceptance, in accordance with the pervious concrete construction preparatory work.

1. The construction site has reached "three connections and one leveling", that is, water connection, electric connection, road connection and construction site leveling. The construction site conforms to the conditions of stacking raw materials, the equipment installation has been completed, and the construction machinery enters the site to meet the construction requirements.

2. The construction of cushion layer and sand filter layer has reached the design elevation, the compaction of cushion layer has been finished, and the leveling and compaction degree meet the design requirements. (the construction surface is ready and meets the construction conditions)

3. When the construction personnel and materials enter the site, they pass the inspection and meet the construction conditions.

2.2 Construction Conditions

1. The site of the mixing yard should be close to the paving site and should not exceed 30 minutes from the date of discharge to the completion of the paving. The summer construction should not exceed 20 minutes.

2. It is recommended that one group be assigned as follows: two people put in cement and reinforcing agent, one person drives a forklift to load materials, one person transports materials by a bucket truck, two people on the spot scrape the board initially and wipe the edges and corners, one person is responsible for the cement flattening machine and one person is responsible for repairing holes and covering plastic film. In total: eight.

3. Avoid construction in dry weather with temperature below zero or above 40 ℃.

4. There should be measuring tools for on-site feeding. The amount of stones and cement should be strictly controlled in proportion. The cementing material (reinforcing agent) should be put into good measuring tools to ensure the same amount of cement each time. The water discharge shall be timed by a time relay or recorded with water on the barrel to ensure the stability of each discharge.

2.2 Tools And Machinery

According to the quantity of the project, the configuration of the entry machinery is determined. The general configuration is as follows:

1. Forced 500 concrete mixer; 2. Loading forklift ; 3. Transporter; 4. Low-frequency plate vibrator; 5. Concrete finishing machine; 6. Cement trowel (several);7. Seam cutting machine (or telescopic seam separator) 8. Airless spraying machine; 8. Airless spraying machine; 9, water pump, high-pressure water gun 10, electronic scale; 11. Cover the curing film; 12. Long horizontal scraper.

2.3 Construction Materials

| The name of the material | Material requirements |

| Cement | The cement should be Portland cement or ordinary Portland cement with the former grade no less than 42.5. 425R cement is not an option |

| Stone | The requirements of no dust, low mud content, stone crushing value to meet the design requirements of the strength.Basic stones: particle size is The permeability of surface stones of 10~20mm is higher than that of other stones.Stone of 16~31.5mm can be used for 25% concrete.The child.Surface gravel: grain size of 3-5mm or 4-6mm rice sand, single grading.Note: it is recommended to use basalt stone for better effect.. |

| Water | Just plain clean water |

| Special reinforcement for permeable concrete | Special reinforcement for permeable concrete |

| Surface protectant, pigment | Purchase according to engineering requirement |

| Expansion joint article | It is filled with flexible materials with good elasticity such as extrusion plate |

| Thin film | Plastic film. |

| Structural adhesive |

C.Proportion of permeable concrete (1 cubic meter)

| The intensity of | Stone | Cement | Strengthening agent | Water |

| C20 | 1650 kg | 358 Quantity of cement | 10 kg | 130 kg |

| C25 | 1650 kg | 378 Quantity of cement | 12 kg | 137 kg |

| C30 | 1650 kg | 398 Quantity of cement | 15kg | 145 kg |

Note: the above data is for reference only. During site construction, the water-cement ratio should be adjusted in strict accordance with the requirements of site technicians according to the actual situation (such as the degree of stone cleanliness, etc.).

D. Construction Technology

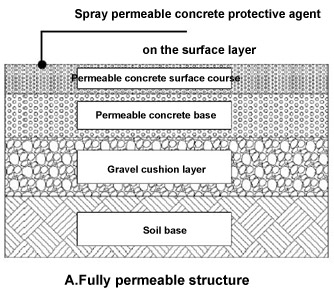

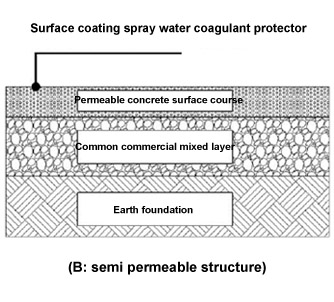

4.1 Conventional structure of permeable concrete.

4.2 Concrete mixing

1. Play the design line.

2. On the basis of plain soil paving should be compacted, and then wet the ground, the cement foundation should wet the cement ground, or sweep cement mud, strictly prohibited when the ground is dry paving.

3. Mixing and feeding of permeable concrete must be carried out in strict accordance with the requirements of mixing ratio or on-site technical personnel, and no wrong casting is allowed. The first feeding must be weighed, and a reference mark can be made in the feeding machinery container.

4. Feeding sequence: firstly, add aggregate, cement and pervious concrete reinforcement into the mixer to mix dry for 15s, add 50% water to mix for 50s, and then add the remaining water to mix for 100s. The amount of water in different sites is different, the first mixing should find the right amount of water, after each mixing as the basis for the deployment of materials, the appropriate state for the slurry is not out of the slurry: the cement slurry is wrapped on the stones, and the cement slurry is not bleeding, not flow slurry. Without cement slurry, the water is too little, paving after easy to drop particles, should add water, flow slurry is not permeable after paving, should be abandoned or paved on the cushion.

5. Stirring time

From feeding and mixing to discharging, 350 type drum mixer normally takes 3.5 minutes. The model 500 forced mixer takes 3 minutes.

4.3 Transportation of finished materials

1. The mixed finished products shall be transported to the construction site in time after discharging, and shall be transported to the site for construction within 30 minutes, and shall not exceed 20 minutes in summer.

2.pavement site, first with manual scraping board preliminary scraping, and then with cement wipe machine back and forth wipe flat, wipe flat after still have potholes, the application of mixed materials to fill the place, edge and corner machine wipe less than the place, must use manual trowel wipe flat, otherwise the strength is not good, easy to drop particles.

4.4 Construction sequence

The basic construction sequence is: paving → leave joint → tamping

The construction sequence of the surface is: paving → leveling → finishing → retraction → curing → cutting → caulking

The order of construction of protective layer is: deployment of protective agent of surface layer → spraying

The construction interval between the base and the surface is: it is suggested to lay the base in the morning and lay the surface in the afternoon. This method can effectively ensure the strength of permeable concrete, shorten the construction period and reduce the cost.

4.5 Paving

Use shovel, rake for paving, permeable concrete mixture should be spread evenly.

A: when paving the permeable concrete base course, the position of expansion joint should be determined in priority, the size should be specified, the mark should be made, and the joint should be retained according to the requirements (when the paving area of the base course is recommended to reach 25m2, the joint should be retained). The paving height should be 1cm to 1.5cm higher than the elevation to ensure that the low-frequency flat ramming is used to meet the design height.

Note: indwelling expansion joint is separated by expansion strip; It can avoid the road surface "heat expansion and cold contraction" formed by empty drum, cracking phenomenon;

B: When paving the permeable concrete surface layer, it is necessary to calculate the height in the early stage. Just like the base layer, the reasonable control of the height can make the compacted surface layer conform to the design height and meet the design requirements of the road surface layer.

After spreading evenly, use a scraper to make the surface even and then use a polishing machine to polish the surface compaction, in order to ensure the tightness of the permeable concrete pavement, so as to ensure the strength of the concrete (when the weather is hot polishing must be timely, otherwise the stones will be killed by the sun, so as to produce the phenomenon of dropping stones), leave two people on the edge of the edge, patch.

4.6 Maintenance

The maintenance of permeable concrete after pouring and forming is the key to ensure the quality of permeable concrete.

Immediately after the completion of the engineering with mulch, sprinkler maintenance, routine concrete curing period for 28 days, we suggest that the maintenance of more than two weeks, the curing period, every day should be 2 ~ 4 times sprinkling water on the cover good film, film paste evenly cover on the surface rocks, curing film with a large number of dew is the best state of floating on the surface layer stones.

The damage of the film should be avoided as far as possible within 3 days before the curing period. The damage of the film will directly lead to improper curing and maintenance leakage, thus resulting in sub-drop phenomenon.

4.7 Slit and caulking

When the strength of permeable concrete reaches about 70% (2 weeks in winter, 5-7 days in spring and autumn, and 2-3 days in summer), a seam cutting machine is used to cut joints. When cutting the expansion joints at the base level, the joints should be consistent with the upper and lower joints of the surface layer and should not be staggered to ensure that the expansion joints of permeable concrete are connected up and down. After cutting the joint, the stone powder in the joint must be washed with water in time to ensure that there is no dust in the joint, and the concrete surface mud caused by cutting the joint should be washed clean. The setting of single block expansion joint area first meets the design requirements, and then it must be 25 m2~30 m2 according to the specification, not more than 30 m2, the best is to control within 25 m2, the area will lead to cracks in the concrete surface layer, or even the phenomenon of empty bulge.

With to expansion joint and the extruded board populated, contraction joint article filled bubble inside, at the time of caulking contraction joint reserved 2 ~ 3 mm height, and then inject glue sealing structure, the embedded seam width, surface flat, feel is good, so request sealing material must stick relay is strong, good resilience, to adapt the expansion and contraction of concrete, and insoluble in water, no water seepage, ageing resistance, resistance to high temperature and low temperature freeze resistance is good.

Note: due to uncontrollable factors such as the weather, if the stones fly out when cutting the seam, it means that the strength is not enough and it needs to be cured for several days.

4.8 Spray coating protectant

Spraying time: it is recommended to maintain the coating for 7 days before spraying the protective agent, that is, after the completion of cutting and caulking. If the project progress is very urgent, it is still necessary to ensure that the coating protection agent is sprayed after 3 days of maintenance.

Matters needing attention

1. During the construction and maintenance of permeable concrete pavement, attention must be paid to the protection of finished products. Walking, animal walking and vehicle driving should be strictly prohibited on the pavement. Due to repair difficulties, the surface is not easy to bond to the original level, so the product protection has been to adhere to the completion of acceptance delivery can be ended.

2. If the semi-permeable structure is used to lay the permeable concrete, clean the shang mixture first, then mix it with 42.5 cement and water, and evenly pour it over the shang mixture.