Bending of sheet metal refers to the processing of changing the angle of sheet metal or sheet metal. Such as bending the plate into V-shape, U-shape, L-shape, etc.

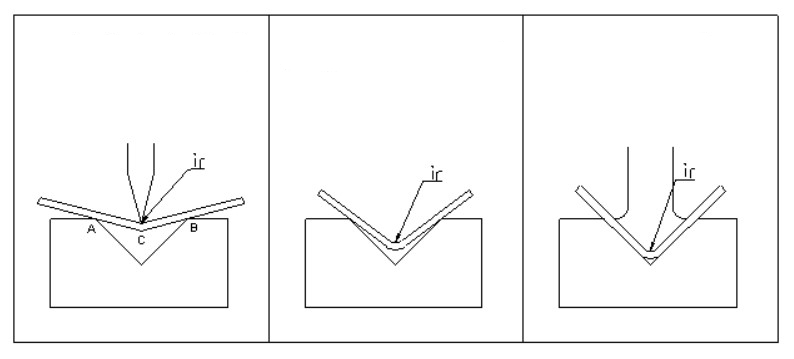

The bending deformation of V-shaped sheet metal bending part is illustrated as an example. The process is as follows:

1. Punch movement contact sheet metal (blank) due to the different contact point forces of punch and die, resulting in short bending moment, elastic deformation and bending under the action of bending moment.

2. As the punch continues to descend, the blank and the die surface gradually approach the contact, so that the bending radius and bending arm are reduced, and the contact point between the blank and the die is moved from the two shoulders of the die to the two inclined surfaces of the die (the beginning stage of plastic deformation)

3. As the punch goes down, the two ends of the blank start to bend (back bending stage);

4. In the flattening stage, as the gap between the convex and concave dies becomes smaller, the sheet metal is flattened between the convex and concave dies;

5. In the correction stage, at the end of the stroke, the sheet metal is corrected so that the straight edge of the fillet fits the punch to form the required shape

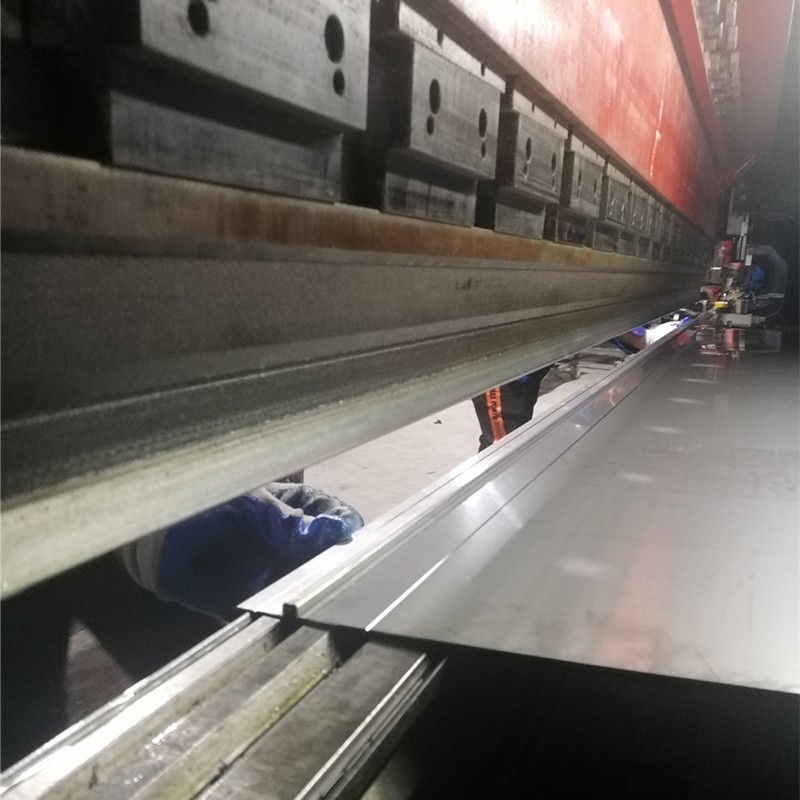

Bending equipment

Our factory adopts CNC bending machine, which is a common bending equipment in major factories at present. It can program angle directly. It has angle compensation, numerical control blocking, v-axis deflection compensation, convenient program call, and adjust data according to output,product variety (length, bending tonnage, etc.).

How to choose the Knife of bending

There are two types of upper die, the straight knife and the straight knife. The straight knife is mainly used for bending parts with simple structure and small size. The curved knife is used for bending parts with complex structure and easy to interfere with the cutter more than twice.

1. First short side then long side: when the workpiece is bent multilaterally, the short side shall be bent first, and then the long side shall be bent;

2. Small parts before large parts: when there are multiple parts in the bending product, the small parts shall be processed first, and then the large parts shall be arranged for processing;

3. First the periphery and then the middle: under normal circumstances, the bending starts from the periphery of the workpiece to the center of the workpiece;

4. First inside and then outside: when bending, first bend the inner part, and then bend the outer part;

5. Part first, then whole: if there are some structures different from other bending structures inside or outside the workpiece, generally bend these structures first and then fold other parts;

6. Special before conventional: bend the special shape first, and then bend the conventional easy formed parts;

7. Considering the actual situation, arrange the bending sequence reasonably: the bending sequence is not invariable, and the processing sequence shall be adjusted appropriately according to the bending shape or the obstacles on the workpiece.

Bending classification

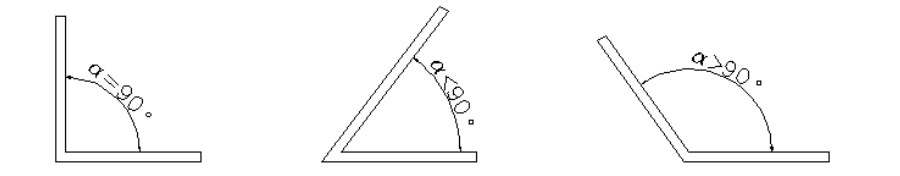

1.fold: l-fold is divided into 90 ° fold and non 90 ° fold according to the angle, and its name is determined according to the internal angle after forming. The deformation coefficient of 90 ° bending is 0.4 times of the material thickness, and other angle deformation coefficients refer to relevant standards of program design

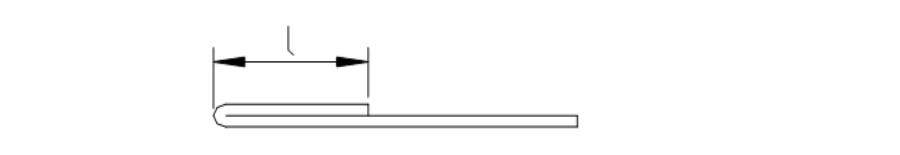

2. N-fold: different processing methods are adopted for n-fold forming according to the dimension values of L and h, one is directly divided into two fold forming, the other is adding gasket to reverse fold and flatten, in general, h in n-fold is the more important dimension.

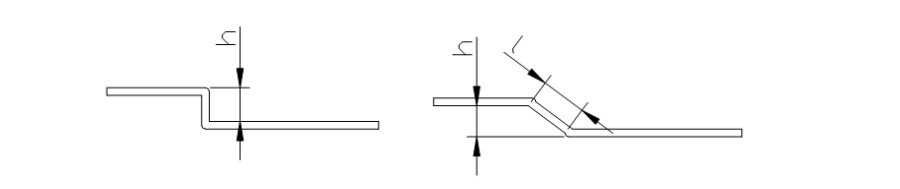

3.Z-fold: Z-fold is also called break difference. According to the forming angle, it can be divided into straight edge break difference and bevel edge break difference. The processing method depends on the height of break difference. When the height of break difference h is less than 3.5 times of the material thickness, use break die or easy die to form. When the height of break difference h is greater than 3.5 times of the material thickness, use normal one positive one negative two fold to complete. When the slope length L is less than 3.5 times of the material thickness, the slope die or easy die shall be used for forming, and when the slope length L is greater than 3.5 times of the material thickness, the normal one positive one negative two fold shall be used to complete.

4.complete bending : complete bending is also called reverse folding and flattening. Its forming process is completed in two steps: first, bend to about 35 degrees, this step is inserting depth, and then press out the dead edge with flattening die. Pay attention to the parallelism of the large surface after forming.