The car business utilizes different machining systems to make diverse car parts, for example, windscreens, external body sheets and inward segments. The most basic methods used incorporate CNC machining and rapid prototype.

CNC Machining

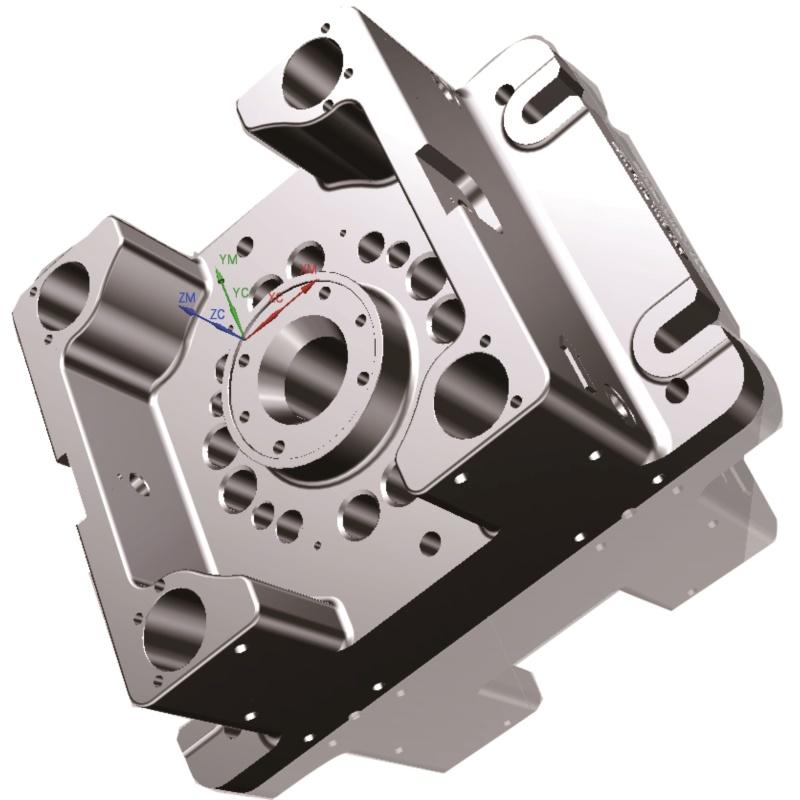

Computer Numerical Control (CNC) is the computerization of machine hardware or gadgets through PC pre-programmed machine switch commands. CNC machining enables the creation of increasingly solid, ground-breaking and swifter cars. CNC frameworks are progressively becoming popular in the car business as they help to accomplish item consistency. The significant level of computerization associated with this procedure guarantees that the production of parts is error-free, impeccable and low labor intensive. CNC machines and apparatuses are utilized in the creation of numerous cutting edge vehicle parts, for example, suspension segments, carburetor lodgings, motor lodgings and bearing tops. The automated nature of the CNC technology offers significant levels of flawlessness thus enabling the assembling of many high-end vehicles from a single production line every single day.

Through CNC machining, car makers have the ability to deliver high-quality products to their clients. The CNC technology enables highly trained and skilled specialists to precisely guide machines with the assistance of controls and applications that are coordinated through a computerized framework. CNC machining can effectively, efficiently and accurately cut, mill, route or drill a variety of materials within a short time. With the CNC technology, manufacturers are able to produce vehicles with modern starter motors that are far more precise and reliable compared to older models that are less effective. Through CNC machining, vehicle parts and components can be made with higher tolerances and better efficiency thus enabling the production of cars with more speed and horsepower.

This is an intuitive procedure that is utilized to rapidly imagine what an idea, framework or application will look like so as to get approval and input from partners, originators, engineers and clients. This procedure includes making a visual plan of a product after which a survey is conducted where clients and different partners assess its viability and whether it lives up to their desires. Based on this feedback, specialists and partners pinpoint the areas that need further explanation or improvement. Because of its efficiency and cost-effectiveness, rapid prototyping is turning into a basic innovation among car, researchers, plane design specialists, medicinal analysts as well as independent hobbyists.

Rapid prototyping has been adopted by the automobile industry as it offers clients maximum control and a hands-on feel so that they are able to customize their own cars in whichever way they feel. Prototyping vehicle parts is less tedious and much more affordable compared to some conventional sequential construction system generation strategies that have become obsolete on account of the progression of rapid prototyping. Rapid prototyping plays an important role in the automobile industry especially during the plan approval stage.

For example, car prototypes can be made in order to inform the decision as to the best materials or hardware that ought to be utilized as well as the unique features that would best suit a specific vehicle. Rapid prototyping is a critical component of the entire automobile engineering process that also assists engineers make informed decisions regarding the creation of new and high-quality car parts that are also appealing to the consumer.

Before attempting any CNC project, it is important to be well-organized as this can save you money and a great deal of time over the long haul. Individuals who are new to CNC machining process, will in general expect that the computerization involved will naturally make it easy to create parts.

In fact, the expense of owning and operating a CNC machine can be overwhelming. Even making just a single CNC part could cost you many dollars. Production expenses can be mitigated through a few different ways by first establishing the components that may significantly increase CNC costs more than others. A professional CNC service provider should be able to help you identify components at the initial stages of the generation cycle so as to limit their use.

Here are some useful hints to assist you with eliminating costs in your next CNC project.

1.Your material expenses ought to be significantly reduced

This does not mean settling on low-quality by utilizing cheap and unacceptable material. You just need to pick the most accessible and least expensive material that can meet your actual design needs with the same desired results. In case the project that you are undertaking includes functional prototyping, ensure that as much as possible you utilize less expensive choices, for example, aluminum and ABS. Pricier materials, for example, hardened steel must only be utilized during the production of implantable medicinal gadgets where bio-similarity is fundamental.

2.Avoid parts with complex/organic geometry

Your parts may every so often have a few components that could require unusual non-standard fixtures and this could further aggravate costs. Parts that may require special fixtures such as those with organic geometry ought to be avoided as they may not generally be held well in the standard vice which means the the part surface must be machined through a complex and tedious procedure for a superior hold. Parts containing abnormal features or features that are not parallel to stock surfaces ought to likewise be avoided where possible.

3.Setup time ought to be decreased

It is critical to think about how your CNC part will be made rather than what it will be produced using CNC machining process. The amount of set-up time before the machining process starts is to a great extent dictated by design and planning. Non-recurring engineering costs (NRE) largely make up the biggest part of machining costs during prototyping thus they ought to be limited as much as possible. Set-up time which involves machine set-up and part fixtures as well as computer-aided manufacturing further increases these costs. Set-ups should be significantly reduced as every set-up will require its own procedures and computer-aided manufacturing program (CAM).

4.Increase quantity to reduce unit cost

As the name suggests, NRE expenses are non-recurring which implies that if you are producing multiple similar parts, the same CAM program and fixtures may be utilized again and again. One stock piece can be sliced into numerous other parts without delay which will significantly bring down your unit cost altogether. Ensure that you produce enough CNC parts so that you do not have some that are not needed.

5.Reduce machining time

Another significant cost-saving tip to consider during the production of CNC parts is reducing the real part machining time. This is determined by two key factors which are material and part design. It is critical to pick the most machinable material where functional requirements permit as this will save you a lot of cash. Hard materials generally take longer to machine since there is the danger of devices breaking although there are some exceptions to this rule worth considering. For instance, aluminum is harder when compared to most plastics but it is much easier to machine although it costs more than plastic. Cutting plastics fast also leaves an unattractive surface finish. Steels containing a high carbon content alloy are generally harder to machine thus it is better to work with low carbon alloys like 303 hardened steel which is easier to machine. Metals containing magnesium or Zinc such as Brass are also relatively easy to machine.

Pros of CNC Machining

CNC machines can be used continuously which means that they can keep running as long as you want them to run. They can run for weeks, months or even a whole year. The only time that you will probably need to shut down your CNC machine is during a routine maintenance.

CNC machines are also consistent in that they are able to create replica CNC machined parts of a similar object without any blemishes or design flaws which gives your business the consistency to deliver quality products over and over. CNC machining allows you to cut down on the number of engineers needed. This means that you will have less skilled staff and less defective parts.

CNC machining uses software which is a key component of the machine. This software can be updated constantly to improve your quality of work. Some topnotch software even enable designers to simulate the entire manufacturing process thereby eliminating the need to use prototype which saves a lot of time and money.The technology utilized in the CNC machining programming will enable you to make operations that cannot be made by manual methods.

Management of the production process of CNC machined parts is easy as even one person can be able to operate several programmed machines at once. Only cutting devices will need to be changed when brunt. Operators only require basic training to effectively work with CNC machines.The flexibility offered by CNC machines is unmatched as the machine can be adjusted or reprogrammed to produce different designs in a matter of minutes. This helps you meet the demands of your clients without spending money on parts replacement.

Cons of CNC Machining

Expenses associated with CNC services can be quite high compared to manually operated machines. However, this is gradually decreasing as the demand for CNC parts increases.

Very little training is required to produce CNC parts hence a lot of skills that were initially needed to operate the old manual machines are lost. This also means that learners are no longer trained to produce parts manually due to the growing demand for automated machines. This will be a challenge when the need for handcrafted parts arises.

Adoption of CNC machining will also lead to job losses as less skilled laborers are required to operate CNC machines. This will eventually lead to staff rationalization and unemployment.

When considering the pros and cons of CNC machining, you will discover that the advantages far outweigh the disadvantages. While initial costs may be considerably high, you will save more in the long run from reduced skilled staff as well as the number of rejected CNC parts. This technology allows you to be more creative and innovative as you can easily change your design components.

How to Choose The Best CNC Machining Provider

Here are a few useful tips that will assist you when searching the right CNC service provider who is suitable for your line of manufacturing. There are several different types of CNC machines and the type of work is also not the same for all CNC service providers. Choosing the best CNC machining provider means that you will be able to deliver high-quality CNC machined parts to your clients time after time without delay which will help you grow the number of loyal customers.

Here are a few tips to consider when choosing a CNC machining provider.

Skills and software

For the best CNC machining services, you will need to choose a service provider that uses the most recent and advanced technology regardless of the type of machining service offered. It is also import to consider the skills and capabilities of your service provider as you want to work with one that can produce anything that you need to your specifications be it CNC turning services, CNC drilling or any other service. It is advisable to choose a local service provider since you will be able to visit the company and know more about its capabilities. CNC machining service providers work on different materials hence it is important that you choose one that can work on your preferred material and components. These could either be aluminium, brass, copper, steel and so on.

Availability of technical support

When dealing with a professional company, you will rarely experience an issue with parts or components but in the event that an issue arises, you will want efficient and reliable technical support.

Cost

It is also important to consider how much you will pay for the services whether you need custom-machined or standard parts. You want to get a high-quality product at an affordable price. The cost of the CNC machining service will greatly affect the overall selling price of your CNC machined parts. A good CNC service provider should be able to help its clients save time, money and effort. Quality is all that matters hence you will need to hire a service provider that will help you achieve this.

Contact us today for the best CNC machining services. Our experts have the skills and expertise needed to meet all of your machining needs.