There are thousands of manufacturers specialized in transformers in China at present. The market is very competitive. If you want to get ahead in the market, you products are required to have a good economic performance and high reliability. Using copper foil and ground wire is our common way to increase the product performance.

What Are The Functions And Benefits By Doing This And Under What Circumstance Will It Be Required?

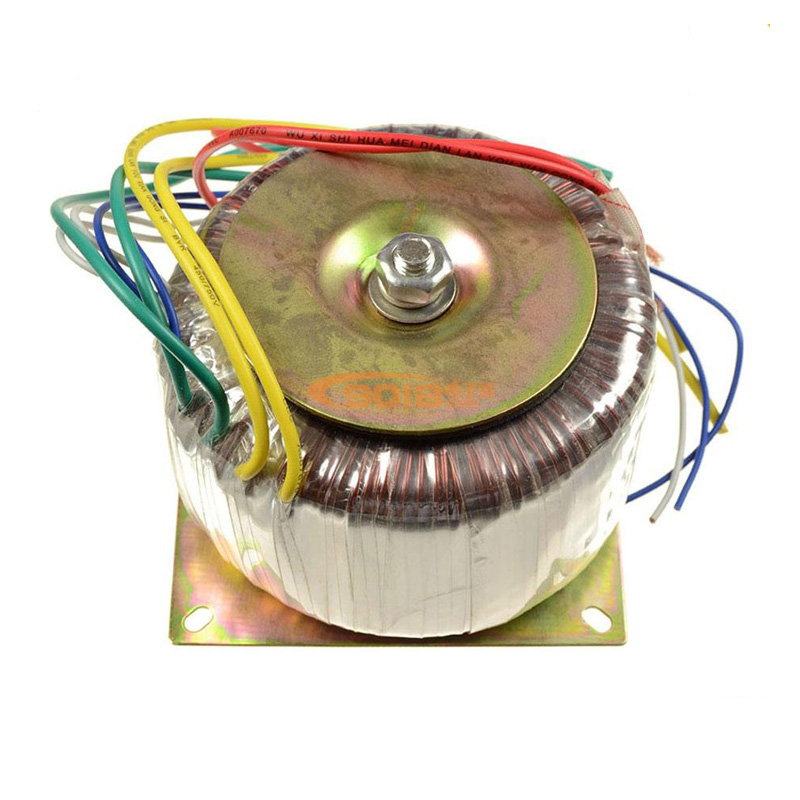

The copper foil is used as the shield in the transformers. Wrapping the copper foil after winding the primary coils and then finishing with the secondary coils, leading the cooper foil to connect to the ground, which can play a role of shielding. Slight static electricity will create while the transformers or the devices are working. The static electricity will be blocked after wrapping the copper foil so that the impact on the devices can be avoided.

The ground lead is used to lead the leakage current to the ground. Leakage current may happen while the devices are operating. Leakage current slightly is a normal phenomenon and has no impact on the working of the devices. However, while in the in the medical testing, instrumentation and other related industries,even it is the slight leakage current,it can affect the security and accuracy. These affects can be avoided after connecting to the ground.

While Choosing The Copper Foil As The Shielding, There Are Some Points Need To Be Paid Attention As Below:

1. The purity of copper foil should not be below 99.95%.

2. The surface of copper foil should be smooth and neat but no delamination, cracks, peeling, bubbles, inclusions, pricking and folding, etc.Slight, local, failure of scratches, blotches, pits, embossing, and roll prints which do not greatly exceed the allowable thickness of the foil can be allowed. Copper foil should be straight but slight waves are allowed. The foil should be trim without spiny, cracked, and rolled.

3. Another thing to note that the copper foil should be stretched tight and not tend to one side. The welding spots should be smooth. The time of soldering can not be too long which will burn mara tape.