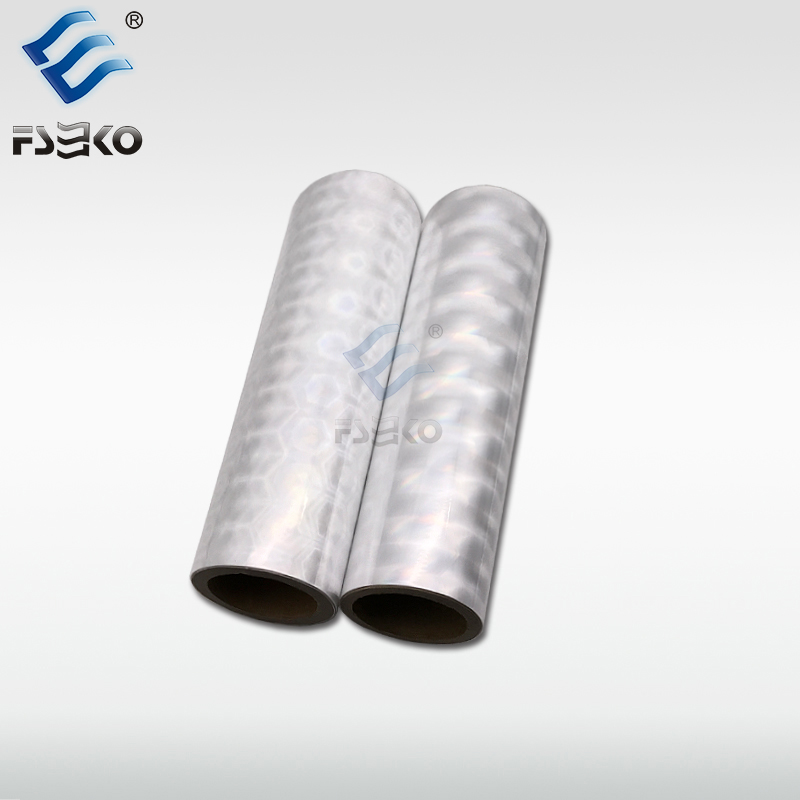

GUANGDONG EKO FILM MANUFACTURE CO., LTD is internationally competitive in the bopp thermal lamination film field. EKO has created a number of successful series, and hot stamping foil suppliers is one of them. FSEKO bopp film manufacturers is produced in the course of a sustainable and unique revolution, without involving harmful or toxic substances. There are elastic components in the material that makes EKO films less breakable for better long-term use. This product has been widely applied in animation design, business terminal, and education sector mainly owing to its convenience and powerful functions.

We are committed to the green production approach. To reduce carbon footprint and pollution, we will introduce green and sustainable manufacturing machines to help us achieve this goal.