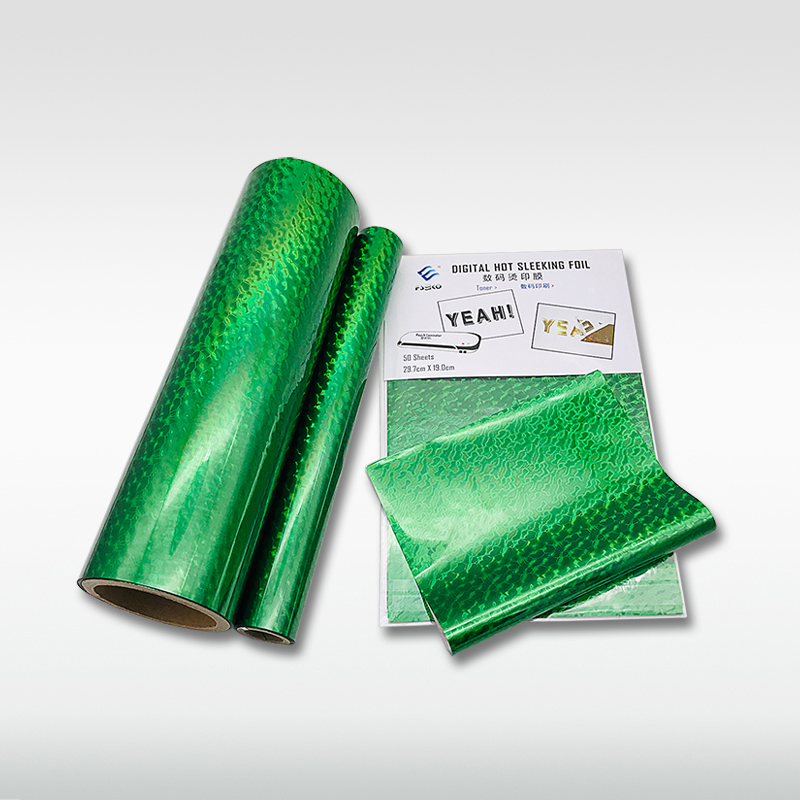

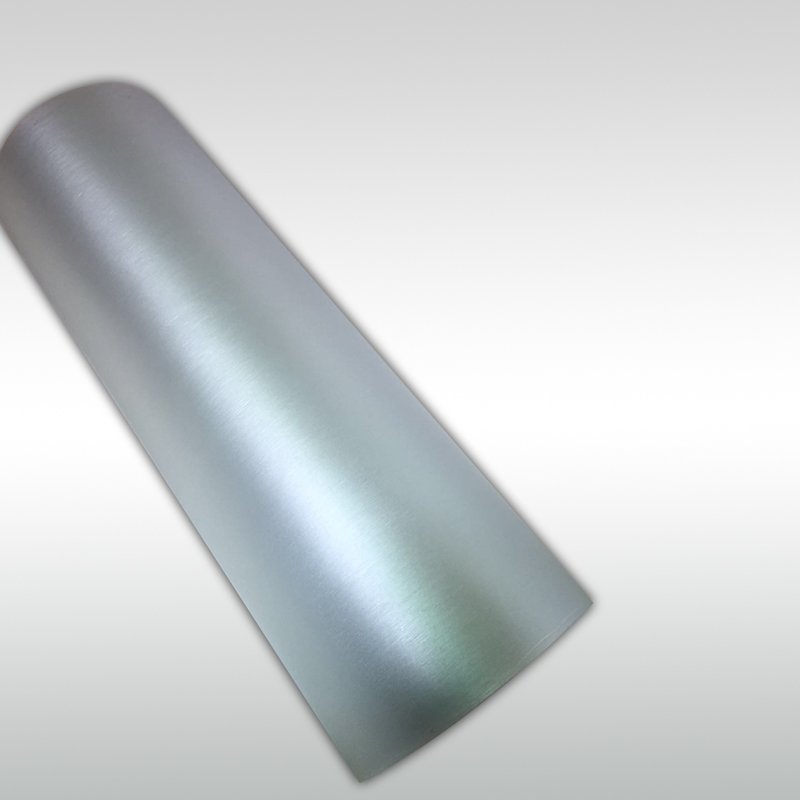

FSGUANGDONG EKO FILM MANUFACTURE CO., LTD constantly keeps developing and optimizing laminating roll film suppliers. Various in styles, EKO's thermal laminator can meet the needs of different customers. The product provides a perfect cushioning effect. It will not suddenly crack or break after repeated impact from the foot and ground. EKO films and materials are structured and engineered to perform with great efficiency. The product is highly preferred among customers for its competitive advantages. EKO laminated films are used in a wide variety of packaging applications and industry segments.

our team takes initiative by utilizing opportunities. Check now!