3D Printing History

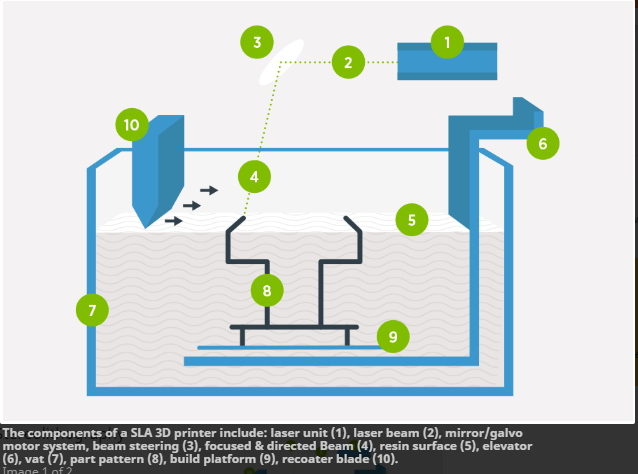

While stereolithography (SL) is one of the oldest 3D printing types of 3D printing technology, it remains the gold standard for overall accuracy, surface finish, and resolution in today’s 3D printing industry growth. It uses an ultraviolet laser focused to a small point, drawing on the surface of a liquid thermoset resin. Where it draws, the liquid turns to solid. This is repeated in thin, two-dimensional cross-sections that are layered to form complex three-dimensional parts. Material properties are typically inferior to those of selective laser sintering (SLS), but the surface finish and detail are unmatched.

3D Printing Technology in Tuowei

Everything we do at Tuowei is focused on providing the fastest and highest quality 3D printing service for the prototypes and production parts during today’s 3D printing industry growth. This demands the latest 3D printing technology, managed by tight process controls. Our industrial-grade 3D printing equipment is state-of-the-art and rigorously maintained to perform like new with every build. Orchestrating it all, our trained staff produces your parts according to carefully honed procedures.

What is the typical cost of 3D-printed parts with Tuowei 3D printing service?

This is highly dependent on geometry and material selected, the best way is to submit a 3D CAD model to get an interactive quote.

SIZE | Normal Resolution: 736mm x 635mm x 533mm True Silicone: 75mm x 130mm x 130mm |

LAYER THICKNESS | Normal Resolution: 0.1mm |

MINIMUM FEATURE SIZE | Normal Resolution: 0.25mm for the XY draw plane (0.406mm for the Z build direction) |

In order to know more about the 3D printing applications and 3D printing examples. Let's take a steam face device's 3D printing rapid prototype for example. Steam face device is advanced equipment for water replenishing in the beauty industry. It becomes more and more popular in women because they can enjoy face spa at home easier. This is an industry that has a huge potential for development. So many companies change different designs of this product to attract female customers. Clients choose us to make the prototype by SLA 3D printing. We help them to improve the structure of the 3D printing designs. Firstly, we print the prototype with ABS material by SLA 3D printing technology. Then our hand craftsmen polish the surface to make it smooth. It’s very important for this 3D printing prototype. Because a good surface is necessary for 3D painting. Electroplating is the final step to finishing this SLA 3D rapid prototype, which makes the part look more shiny and attractive. After the 3D prototype is finished, our QC check them with three-dimensional equipment. This will create a digital map on the computer which we will compare with the CAD drawings from our clients to check if any deviations on the dimension.