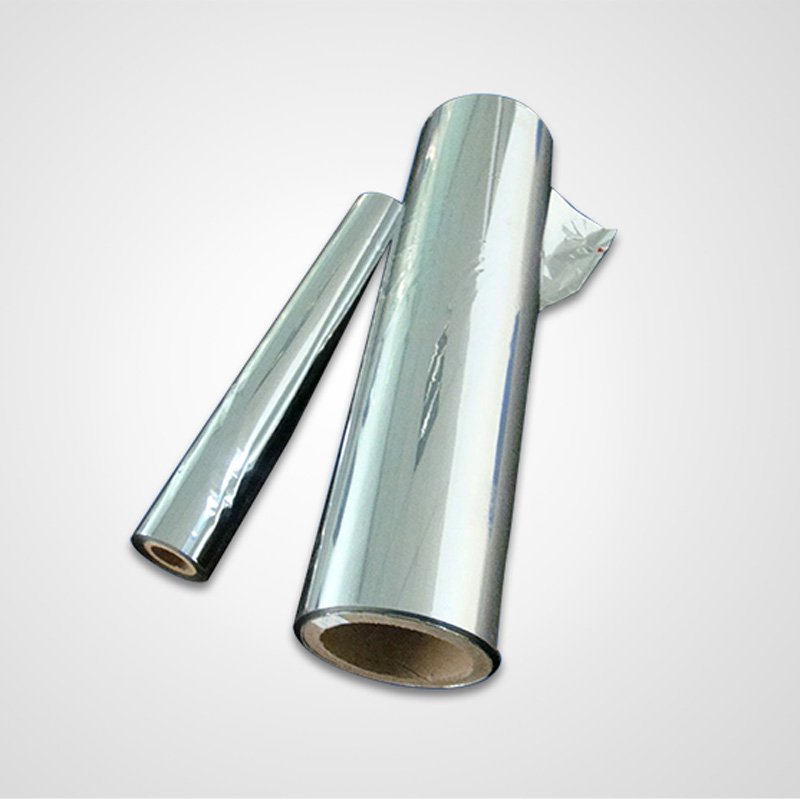

GUANGDONG EKO FILM MANUFACTURE CO., LTD has grown into one of the very professional super stick laminating film manufacturers. The bopp thermal lamination film series is available in a wide range of types and specifications. FSEKO embossed plastic sheet has been tested for dimensional stability, performance and color fastness to meet the regulatory requirements of the bedding industry. EKO thermal lamination films are popular in the marketplace. With a light and super-accurate stylus, the product is built to bring the wildest ideas and maximized convenience to life. Available Finishes are High Gloss and Non-Reflective Matte.

Our company has made environmental issues a top priority to be as efficient and sustainable as possible, from the manufacturing process to the products themselves.