Introduction to CNC Metal Machining:

At Fujia, we use a range of advanced equipment to provide you with a wide range of CNC machining services including milling, turning, EDM, wire cutting, surface grinding and more. Use our imported 3, 4 and 5 axis CNC machining centers.

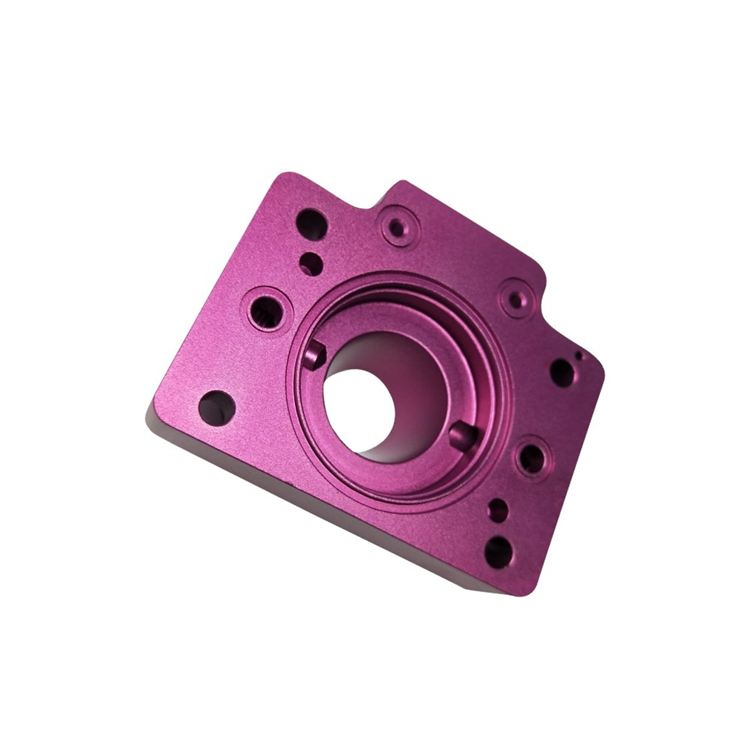

![]()

CNC machining is a subtractive manufacturing process that removes raw materials and makes parts or products through various precision cutting tools. Advanced software is used to control the device according to the specifications of the 3D design. Our team of engineers and mechanics programs the equipment to optimize cutting time, surface finish and final tolerance to meet your requirements. We use CNC machining to not only manufacture parts and prototypes but also to make mold tools that can be used in our plastic injection or pressure casting services.

After developing CNC machining, we can also provide secondary processing and typical surface treatment operations such as sandblasting, polishing, anodizing, oxidation, plating, painting, etc., as needed.

Why do CNC Machining?

The benefits of CNC machining:

Highly accurate and repeatable.

Suitable for many different types of substrates.

Low investment in mold and preparation costs.

Quickly remove large amounts of metal materials.