The development of the prototype model has a history of many years, at the beginning, because of the use of manual production, such as the use of mud carving, only by manual cutting and other processing, so it is called the prototype. In fact, it should be a batch of samples made before the mold is opened, the first sample, so there is another name called the first sample.

Now the prototype has already been broken, the advanced CNC engraving technology, the rapid SLA laser rapid prototyping, and the high efficiency and low volume duplication mold, etc., have made the handmade prototype a great change! No matter the hand finish or the appearance of the prototype, it is made with the steel mold. The product has reached a great extent.

Prototype production is very fast, low cost, because only in this way, the manufacturer of the hand model will reduce the product development cost and time risk, which can be in the competitive market to get the first opportunity. What methods do we often use in making and processing first models? Let's take a look at it.

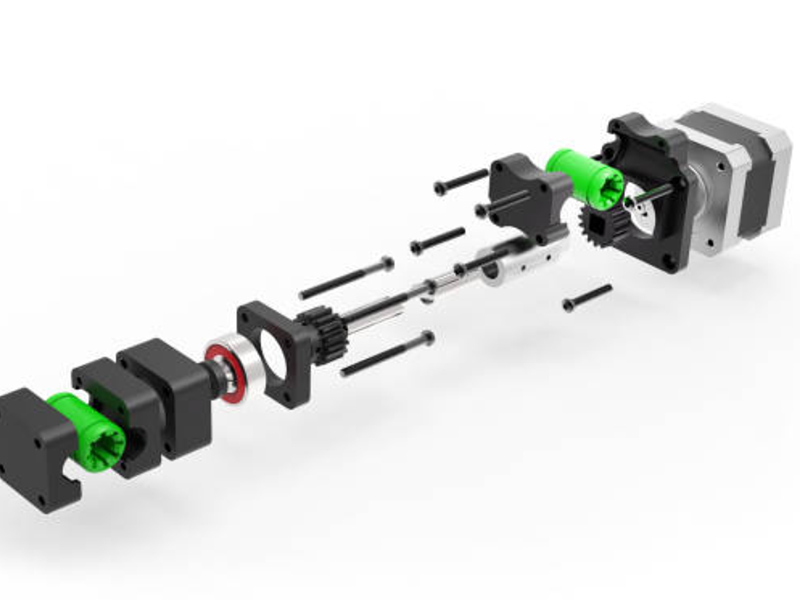

1, CNC machine tool processing

CNC machine tool is called CNC milling machine. The accuracy of parts is guaranteed by computer control. CNC processing main materials are ABS, PC, PMMA, PA, POM, PE, Bakelite. Among them, ABS is the most common and most commonly used plastic material, PC and PMMA are used for processing transparent parts, PC is translucent, and PMMA is completely transparent. The machining accuracy of CNC can reach + 0.05mm.

2, A replica of the prototype model

Small batch prototype making, we usually use the method of vacuum silicone compound mold, because this silicone compound mold production cycle is short, the price is cheap, easy to occupy the market. Under normal circumstances, the service life of silicone die is 15-20 times. Under the vacuum condition, the castable is deformed, stirred, preheated and injected, and it is cured for two times in the thermostat. The strength and hardness of the material of ABS can be reached by the model of the silica gel.

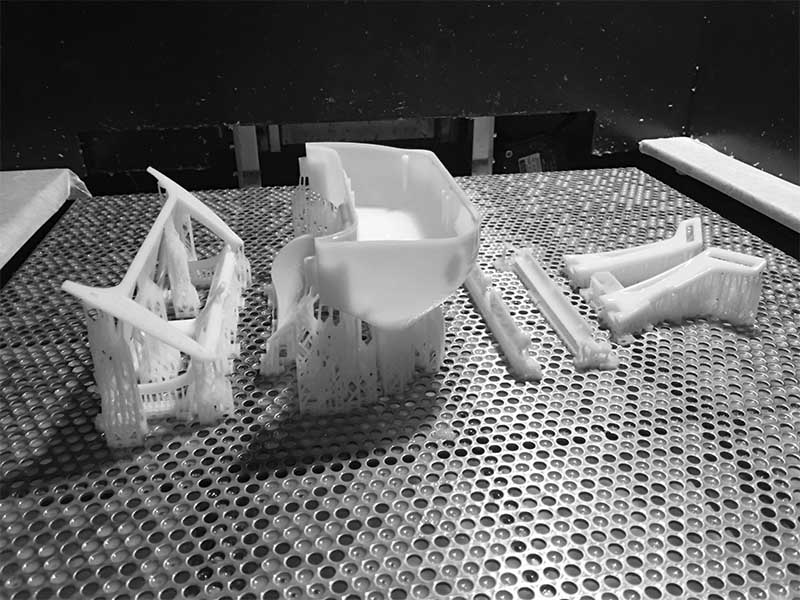

3, 3D print hand model

3D printing is actually laser rapid prototyping, such as today's SLA/SLS and so on, all belong to 3D printing. The 3D printing plate model is first made by laser rapid prototyping machine. After polishing and polishing, it is taken as a model part of the mold. The advantage of 3D printing is that it reduces production cost and time cost.

The purpose of the prototype is to verify the appearance, structure and size of the new product, to see whether the design of the product is inadequate; it can also reduce the risk of the mold opening, and avoid the design problems when the mold is opened, which will cause a great cost loss to the enterprise.

Summary: prototype can improve the work efficiency of the R & D department, reduce the development cost, time and risk of the product, and can satisfy the verification of some structural performance in the product R & D process.

After we know the methods of making prototype models, the next time you need to make a prototype, you have to find a handy prototype factory with good quality and delivery. It's best to find a large, professional prototype factory.

The role of hand model grinding:

(1) remove the burr on the surface of the base, oil and dirt.

(2) reduce the roughness of the surface of the workpiece:

(3) strengthen the adhesion of the coating.

1. Hand grinding and polishing

Low efficiency, high labor intensity and unstable quality, but the most common use.

2. Digital polishing machine

Digital control, semi-automatic polishing, small volume, easy to use, stable quality and good repeatability.

3. Ultrasonic polishing machine

After polishing, it does not collapse the edges and corners and does not affect the accuracy of the hand plate model.

In general, the polishing technology of hand model is the following:

(1) mechanical grinding: mechanical grinding methods such as electric grinding machine disc type and vibration type.

The hand board model plays a key role in the process of product development. It can be said to be the core and future of the processing industry. It is a miniature of the advance of modern manufacturing technology. It can not only determine whether the design of the product is feasible, but also the key to the success of the product to the market.

With the increasingly fierce competition of the social market, the industrial design industry is growing and growing, and the enterprise pays attention to the industrial design while paying attention to the sample production. The design, quality and appearance effect of the product need to be verified by the first model. The industry of the prototype model has gradually developed from industrial design. A relatively independent industry has flourished.

(2) dry grinding: the disadvantage of sandpaper grinding is that there will be a lot of dust in the process of operation, which will affect environmental hygiene.

(3) wet grinding: sanding water with sandpaper or soaping water.