Vacuum Casting :

Vacuum casting is a casting process in which metal is smelted, cast, and crystallized in a vacuum chamber. Vacuum casting minimizes the amount of gas in the metal and prevents the oxidation of the metal.

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model.

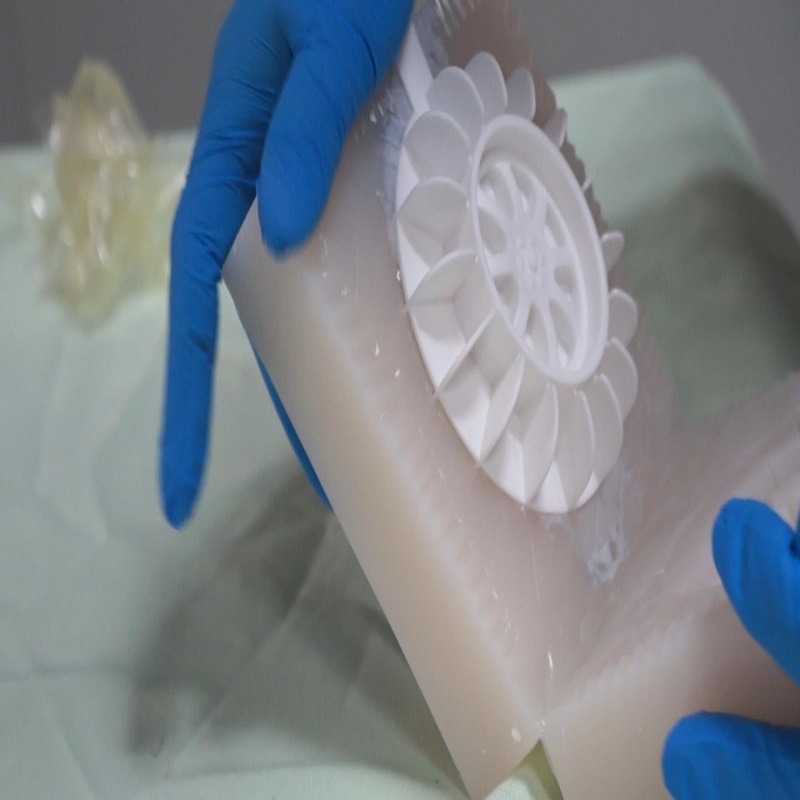

Vacuum casting involves making a mold out of silicone rubber, usually based upon a master model created by CNC machining or one of our rapid prototyping services.

The advantages of vacuum casting:

(1Simplify the process and reduce costs.

(2)Good for testing complex structure rapid products.

(3)The high fidelity of the mold gives excellent surface details requiring little or no post-processing.

(4)Molds are durable up to approximately more copies so it’s great if you need more than one copy.

(5)Color can be customized by casting to meet your color requirements,for instance, rubber, ABS material.