With the development of economy and the improvement of people's living standard, the goal of people's sensory pursuit is also rising day by day. In some high-end places of metal decoration, the more complex the shape of metal sheet ornaments is, the more can reflect the designer's design standard and new style, so as to attract the attention of customers. At the same time, the workpiece should meet the technological requirements of the bending edge arc radius as small as possible, no crease on the workpiece surface, no indentation on the decorative surface, etc. The traditional bending machine can't meet this special technological requirement, so the technology of planing and bending on the metal plate came into being. This paper mainly describes the characteristics of gouging process and slotting method, as well as how to ensure the size and angle of bending in the bending process.

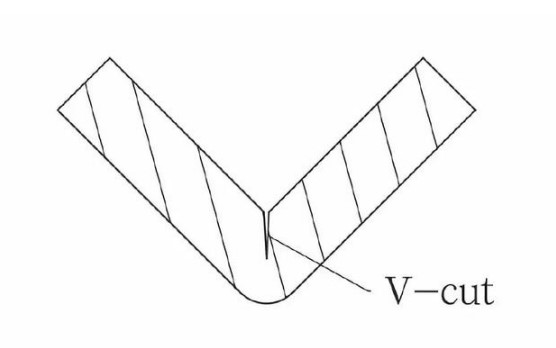

Slot shaping (slot planning) is an auxiliary process of bending forming of metal or non-metal materials. At the bending line where metal or non-metal materials need to be bent forming, special equipment tools are used to plane out the V-shaped groove, so that the material is easy to bend forming and the outer r of the bending angle can be minimized, and then the bending machine or manual bending forming is used to complete the processing and achieve the appearance of the product Requirement. The depth, width and angle of V-groove can be ensured by the feed amount and the shape of planer during planing.

Processing of gouging

1. Generally, the V-groove machining has special requirements for the bending of sheet metal parts, and the normal bending cannot reach the minimum value required. At this time, bend after gouging.

2. The structural dimension design of sheet metal parts is special. When the normal bending cannot be reached, the groove needs to be planed, such as U-shaped structural parts, the inner cavity dimension is only a few millimeters, and at this time, the double V-groove is planed for forming.

3. Depth, width and angle of V-groove

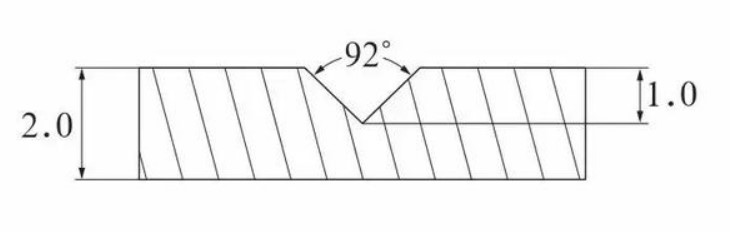

The depth of V-groove planed by different thickness materials is different. The specific processing data depends on the product requirements of customers.

As the only single forming process in sheet metal processing, bending process is one of the most important processes in sheet metal processing. The quality of bending process will directly affect the forming size and appearance of products. Therefore, how to ensure the forming size and angle of the workpiece in the bending process is a key research content in the bending process.

Characteristics of gouging and bending process

The grooving and bending process is a process in which the grooving machine is used to line and plane the V-shaped groove on the position where the metal plate needs to be bent, and then the bending is carried out on the common bending machine according to the demand. The process features of gouging and bending mainly include the following three aspects.

The arc radius of the edge of the workpiece is small, and the workpiece has no crease.It can be seen from the bending process that the size of the edge arc radius of the workpiece after bending is in a positive proportion to the thickness of the plate. The thicker the plate is, the larger the arc radius formed by bending is. After v-notching, the remaining thickness of the metal plate becomes half of the original, or even smaller, which can greatly reduce the arc radius of the edge after the workpiece is bent. Because the thickness of the remaining plate at the bend after gouging is relatively thin, the deformation force during bending will also be correspondingly reduced, which will not spread to the unbending area, so there is no crease on the surface of the workpiece after bending, and because the thickness of the plate at the bend is relatively thin, the reduction of the required pressure during bending can well avoid the risk of indentation on the decorative surface. In this way, it can meet the requirements of metal decoration in hotels, banks, commercial centers, airports and other high-end places, such as small edge arc radius, no crease on the surface and no indentation on the decorative surface.

In the bending process, the bending force required for the metal plate is directly proportional to its thickness. The greater the thickness of the sheet metal, the greater the bending force required, and the corresponding increase in the tonnage of the equipment required. After V-shaped gouging at the bend of metal plate before bending, the remaining thickness of the plate is greatly reduced, so that the bending force required for plate bending will be correspondingly reduced, so that the thick plate can be bent on the bending machine of smaller tonnage. This not only reduces the investment in equipment, but also saves energy consumption and site.

Some parts can't be bent on the general bending machine, but the bending can be realized by opening V-shaped groove at the bending point and then bending by hand. In addition, the method of controlling the residual thickness of the sheet can also be used to control the rebound force and the rebound angle. If the thickness of the remaining plate after gouging is controlled at about 0.3mm, the springback angle will be very small, and the springback can be ignored.

Slotting method of V-groove

In sheet metal production, gantry planer and metal sheet slotting machine are often used to slot metal sheet in V-shape. Place the plate to be planed and bent on the slotting machine for positioning, and then input the thickness of the plate for automatic tool gouging. When planing, pay attention to the following two aspects.

Slotting depth and residual thickness settings

In the case of a certain plate thickness, the slotting depth and the residual thickness are a corresponding value. According to the bending process requirements, set a residual thickness value first, which is generally set as 0.8mm by default, and the minimum should not be less than 0.3mm. Then according to the thickness of the plate set the number of tool and feed depth. Due to the need to control burr and protect the tool, the feed amount should not be too large. Generally, the depth of the first groove should not be more than 0.8mm, and it should be carried out in two parts at least, and it should not be planed in one knife. For example, for a stainless steel plate with a thickness of 1.2mm and a thickness allowance of 0.5mm after slotting, the first tool is set with a feed of 0.5mm, and the second tool is set with a feed of 0.2. After two knives, the remaining amount just reaches 0.5mm, and the burr is relatively small.

Setting of slotting angle

It can be seen from the bending process that when the sheet metal is bent, there are different degrees of springback deformation, resulting in the deviation of bending angle. When the V-groove is opened, the groove can be rationalized according to the required bending angle of the workpiece. Generally, the slotting angle of V-shaped groove is 1 ° - 2 ° larger than the bending forming angle. For example, when bending a 90 ° workpiece, the angle of V-shaped groove can be opened to 92 ° (Figure 4), so that the angle error caused by bending rebound can be well avoided.

Types and selection of slot cutters

The types of slot cutters are mainly divided into diamond top angle slot cutter, square slot cutter, triangle slot cutter, circular slot cutter, etc. the appropriate cutter can be selected according to the different shapes and angles of V slot when planing. When planing ordinary V-groove, the angle of cutter should be less than that of V-groove. For example, when the V-groove angle is 45 ° - 60 °, a slotting knife with a diamond top angle of 35 ° should be selected; when the angle is 60 ° - 80 °, a regular triangular slotting knife should be selected; when the angle is 80 ° - 90 °, a slotting knife with a diamond top angle of 80 ° should be selected; when the angle is greater than 90 °, a square slotting knife should be selected; when the circular slotting knife is selected.

Setting the number of tools

When deep gouging is carried out for the plate with a long dimension, the longer path of continuous gouging with a single tool is easy to cause overheating wear, poor gouging effect, large burr and other problems of the tool. For example, when a stainless steel with a length of 2m is planed with a slot of 2mm, if the first cutter feeding amount is set to 0.5mm and the first cutter is planed for 2m continuously, the cutter will become soft due to excessive heat, which will easily lead to the quality decline of the slot after 1.5m and the increase of burr; if the feeding amount is 0.2mm, 10 cutters need to be planed to finish the 2mm V-shaped slot, which greatly affects the processing efficiency. Therefore, when planing the long-sized plates, in addition to setting the feed amount, the number of tools that work at the same time should be set. In this case, 3-4 knives are generally used to work at the same time (Figure 7), and the feed amount of each knife is about 2mm different. If the feed amount of the first knife is 5mm, the feed amount of the second, third and fourth knives are 7mm, 9mm and 11mm respectively. This can not only ensure the quality of gouging, but also improve the working efficiency.