Smokeless mirror polishing technology for aluminum alloy profiles

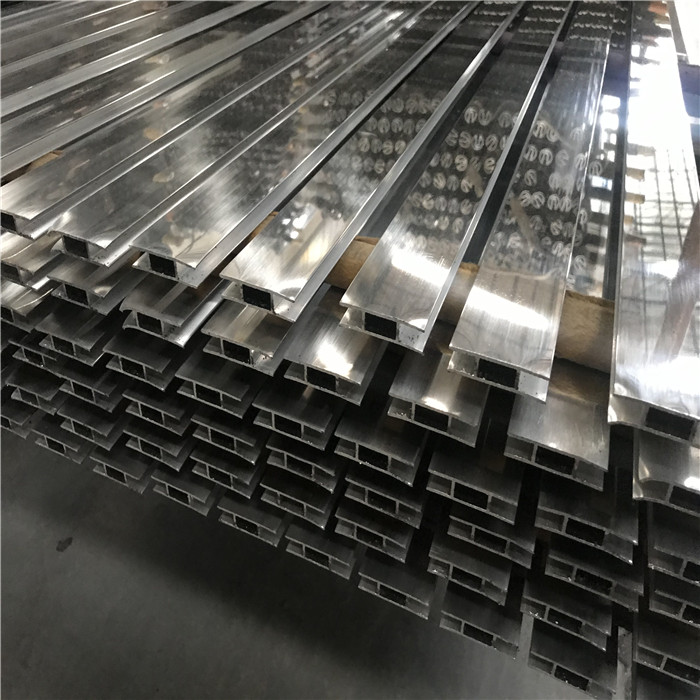

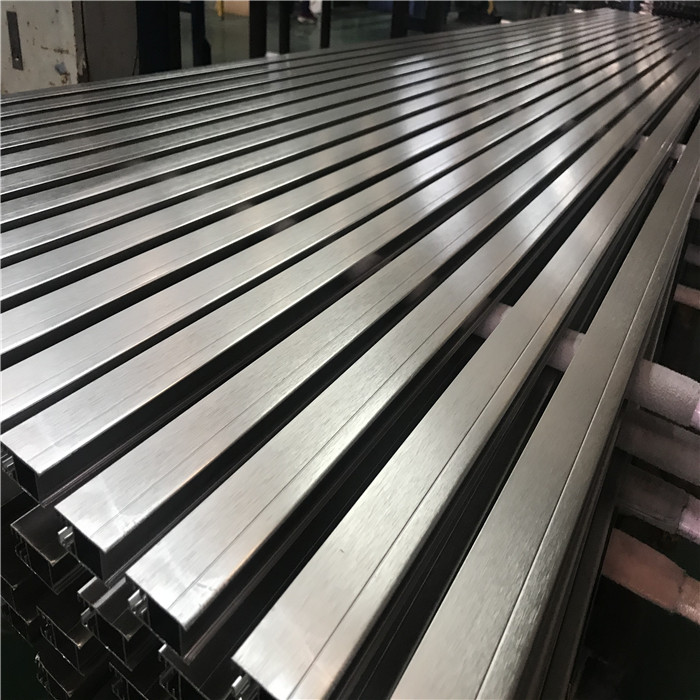

1. Technical features and advantages of aluminum alloy profiles such as aluminum alloy plates

(1) aluminum alloy aluminum profile, such as technical features: smokeless mirror polishing is, no flow mark, low cost, low consumption, low investment of equipment, high brightness, high stability, high efficiency, high yield and other characteristics, break through the bottleneck and deficiencies of the traditional polishing technology, successfully realizes the 11 meters long products chemical polishing and automatic line chemical polishing of large-scale production.

Smokeless mirror polishing technology is the upgrading technology of ordinary triacid and electropolishing, and is the development direction of chemical polishing technology of aluminum alloy profiles such as aluminum alloy plates.

(2) The technical advantages of aluminum alloy profiles such as aluminum alloy plates are as follows:

1) No yellow smoke: Smokeless mirror polishing fundamentally solves the problem of large amount of yellow smoke generated by tri-acid polishing.

It can save a lot of environmental treatment cost.

It has cleared the main obstacle for the wide application of chemical polishing.

2) No flow mark: The smokeless polishing technology completely solves the problem of flow mark in polishing, and realizes the automatic line-scale production of 11m long polishing material, making polishing as easy to operate as alkali corrosion.

3) High brightness: Smokeless polishing can increase the brightness by 20% ~ 30% compared with triacid polishing and electrochemical polishing due to the use of new polishing ingredients. It is the current polishing technology with high brightness.

4) Low consumption: The consumption of smokeless mirror polishing agent is 60-70% lower than that of electrolytic polishing (500-700kg/t material).

5) High yield: There is almost no defect in the process of smokeless mirror polishing, and the product yield is very high.

6) High production efficiency: smokeless polishing hanging materials and large, polishing can be more than one row at a time;

Polishing without waste, the production efficiency is at least 2 times higher than triacid polishing and 6-9 times higher than electropolishing.

7) Tank liquid stability: the smokeless mirror polishing tank is almost adjustable, which can work stably for a long time.

It paved the way for the large-scale industrialization and automatic production of chemical polished aluminum.

8) Stable brightness: the brightness of polished materials produced by different batches is stable due to the irregular grooves.

2. Analysis of process flow and operation points

(1) Slot setting Instructions:

1) The exhaust wall is completely closed in front of the smokeless mirror polishing slot, which prevents the external natural wind from reducing the exhaust efficiency and is conducive to all-weather production in cloudy, rainy and foggy days.

2) The width of the smokeless mirror polishing tank is more than 1.6m, which enhances the buffer capacity of the tank liquid to absorb smoke and is conducive to mass production.

(2) Tank liquid function Description:

1) Paraffin remover and descaling tank: This tank contains a new type of weakly alkaline paraffin remover and descaling agent, which can remove mechanical polishing wax and residual heavy oil and dirt, and will not corrode aluminum alloy.

Easy to operate.

2) Smokeless mirror polishing tank: This tank contains a variety of components, rich ancient strong oxidant, can be used for mirror polishing aluminum alloy.

Compared with other polishing techniques, this tank has the following characteristics:

(1) No yellow smoke, stable brightness: this tank added enough smoke inhibitor, yellow smoke decomposition was completely inhibited;

The brightness difference of different batches of aluminum alloys is much smaller than that of triacid polishing due to the slow decomposition of the strong oxidant and the stable concentration compared with triacid polishing.

(2) brightness increase: the brightness of chemical polishing is related to the concentration of phosphoric acid, nitric acid, temperature, and the water content of polishing solution.

The higher the water content, the lower the brightness;

The content of phosphoric acid in triacid polishing solution is as high as 80% (the water content of phosphoric acid is 15%), and the corresponding water content of polishing solution is less than 12%.

Such a high water content must reduce the brightness of the polished material.

During the production process, the smokeless mirror polishing liquid is concentrated at high temperature for a long time, and the water content is fully 5%, so the brightness of mirror polishing material is significantly increased.

(3) long-term dripping: considering the chemical polishing reaction is too violent, aluminum alloy after leaving the tank, the dripping time cannot exceed 20s, a large amount of polishing liquid was brought into the water bath, resulting in the cost of polishing material is too expensive.

A sufficient amount of corrosion inhibitor is added to the smokeless mirror polishing solution to protect the aluminum alloy after leaving the tank liquid, it can drip in the air at any time without material and without flow mark.

This can save more than 70% of the polishing fluid.

(4) automatic ash removal: aluminum alloy impure or polishing liquid aging, aluminum by triacid polishing, the surface often has a layer of black ash, the general method is difficult to remove, seriously affect the quality of polishing material.

In a smokeless mirror polishing tank, adding a deashing component can automatically remove the polishing ash.

(5) High yield: due to the mirror polishing groove to solve the color difference, flow mark, flower material, polishing ash and other problems, resulting in a significant increase in yield.

Thus the cost is reduced and the production efficiency is improved.

3) Photooxidation tank.

This slot has two main purposes:

(1) Prefabricated chemical oxidation film: light-retaining oxidation tank, which can generate a certain thickness of the oxidation film, but also completely retain the original brightness;

Before mirror polishing to anodic oxidation, the steel alloy can pass through the photoholding oxidation tank and prefabricate a certain thickness of chemical oxidation film to avoid pitting or flower material in the water bath before oxidation, so as to improve the yield and reduce oxidation loss during anodic oxidation.

2 fine ash: there are two sources of polishing ash, one is the inclusion of aluminum alloy, the second is the polishing fluid aging.

Polishing ash is difficult to remove with general methods, can seriously affect the appearance of the polished material quality.

Although a deashing agent has been added to the smokeless mirror polishing tank to remove most of the polishing ash, there may still be a small amount of residual polishing ash.

Photooxidation tank can thoroughly clean the polishing ash, thus ensuring the quality of polishing material.