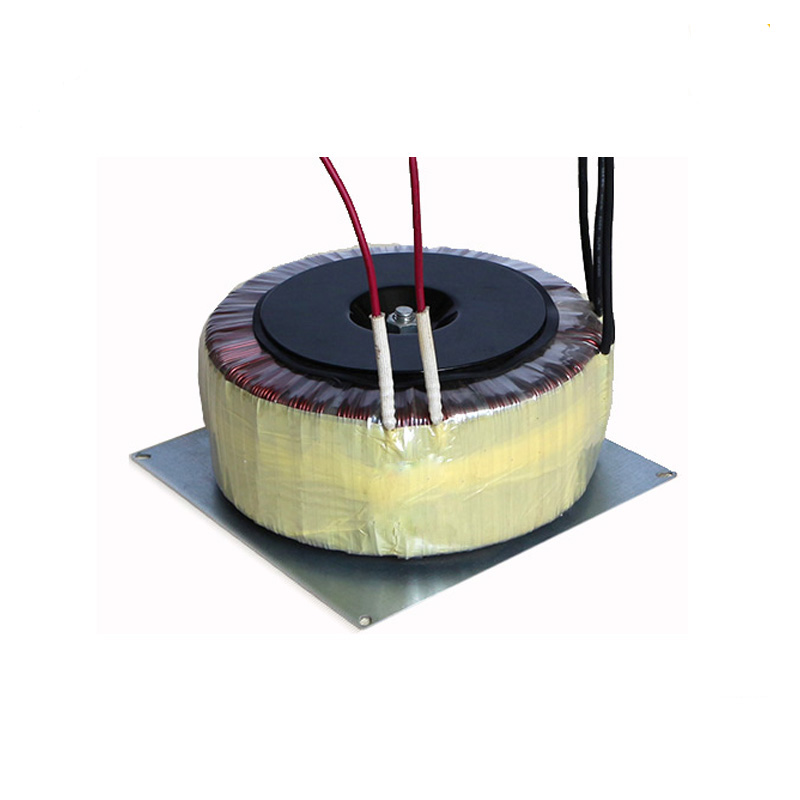

Toroidal transformer with characters of low magnetic leakage, strong load capacity and high efficiency, it’s widely used in power of high-class audio and amplifier, instrumentation, electrical equipment, lighting and medical equipment with strict requirements.

When the toroidal transformer is in normal operation, it will emit a continuous and uniform "buzzing" sound. If the sound is not uniform or with other noise, that regards as it is in abnormal operation. We can find out the faults according to the sound and fix it at time. The main faults as following:

1. Over-voltage occurred in the power grid. When single-phase grounding or electromagnetic resonance occurs in the power grid, the sound of toroidal transformer is sharper than usual. When this happens, you can combine the instructions of the voltmeter to make a comprehensive judgment.

2. Toroidal transformer overloaded operation. The load changes greatly, and due to the effect of harmonics, the intermittent sound of "wow" or "cluck" occurs in the transformer instantaneously, the pointer of the monitoring and measuring instrument swings, and the tone is high and the volume is high. The transformer clamps or screws are loose. If the sound is louder than usual and there is obvious noise, but there is no obvious abnormality in current and voltage, it may be that the internal clamps or the screws pressing the iron core are loose, resulting in increased vibration of the silicon steel sheet.

3. The toroidal transformer is partially discharged. If the transformer's drop-out fuse or tap changer is in poor contact, there will be a "squeaky" discharge sound; if the transformer's transformer sleeve is dirty, the surface enamel is peeled off or there are cracks, a "hissing" sound can be heard ; If the transformer is partially discharged or the electrical connection is poor, it will emit a "squeak" or "crack" sound, and this sound will change with the distance from the fault, at this time, the transformer should be immediately disabled detection.

4. The toroidal transformer winding has a short circuit. The sound is mixed with boiling water, and the temperature changes rapidly, and the oil level rises. It should be judged that there is a short-circuit fault in the transformer winding. In severe cases, there will be a huge roar, and then it may catch fire. At this time, the transformer should be immediately disabled for inspection.

5. Flashover discharge of toroidal transformer shell. This sound occurs when the high voltage of the transformer winding causes the discharge wires to discharge each other or they flashover the casing. At this time, the transformer should be checked for deactivation.