Cold-pressed terminals, also known as insulated terminals, electronic connectors, and air connectors. They are all classified as cold-pressed terminals. It is an accessory product used to realize electrical connection, which is industrially divided into the category of connectors.

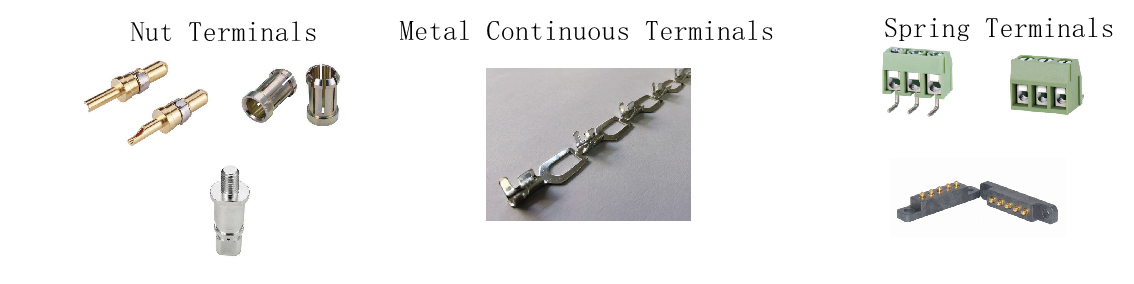

As the degree of industrial automation becomes higher and higher and the requirements of industrial control become more and more strict and precise, the amount of terminal blocks gradually increases. With the development of the electronics industry, the use of terminal blocks is increasing, and there are more and more types. In addition to the PCB board terminals, there are also metal continuous terminals, nut terminals, spring-loaded terminals (or maybe we can call it POGO pins) and so on.

Common problems in the use of terminals

The plastic insulation material and conductive parts of the terminal are directly related to the quality of the terminal, and they respectively determine the insulation performance and conductive performance of the terminal. Failure of any one terminal will cause the failure of the entire system engineering. The painful lessons at home and abroad in this regard are very profound.

Prevention is the purpose, analysis is the foundation. In a sense, preventing failure is more important than analyzing failure. It has more practical significance for ensuring the quality and reliability of the terminal.

From the perspective of use, the function that the terminal should achieve is: the conductive part of the contact part must be conductive, and the contact is reliable. The places where the insulation parts should not be conducted must be insulated reliably. There are three common fatal failure forms for terminal blocks:

1. Poor contact

The metal conductor inside the terminal is the core part of the terminal, and it transmits the voltage, current or signal from the external wire or cable to the contact corresponding to the matching connector. Therefore, the contact must have an excellent structure, stable and reliable contact retention and good electrical conductivity. Due to the unreasonable structural design of the contact, wrong material selection, unstable mold, poor processing size, rough surface, heat treatment plating and other surface treatment processes are unreasonable, improper assembly, poor storage and use environment and improper operation and use, will be in the contact Poor contact due to contact and mating parts.

2. Poor insulation

The role of the insulator is to maintain the correct position of the contacts, and to insulate each other between the contacts and the contacts, and between the contacts and the housing. Therefore, the insulation must have excellent electrical properties, mechanical properties and process forming properties. Especially with the high density and the widespread use of miniaturized terminal blocks, the effective wall thickness of insulators is getting thinner and thinner. This puts more stringent requirements on insulation materials, injection mold accuracy and molding process. Due to the presence of metal residues on the surface or inside of the insulator, surface dust, flux and other pollution and moisture, organic material precipitates and harmful gas adsorption films merge with the surface water film to form ionic conductive channels, moisture absorption, mold growth, and aging of insulating materials. It will cause short circuit, leakage, breakdown, low insulation resistance and other poor insulation.

3. Poor fixation

Insulators not only play an insulating role, but also provide accurate centering and protection for the protruding contacts, and also have the function of installation positioning, locking and fixing on the equipment. Poor fixation, which may affect the reliability of contact and cause instantaneous power failure. The most serious problem is the disintegration of the product. Disassembly refers to the abnormal separation between the plug and the socket, the pin and the jack caused by the unreliable structure of the terminal in the plugged state due to materials, design, process and other reasons, which will cause the control system power transmission and Serious consequences of signal control interruption. Due to unreliable design, wrong material selection, improper selection of molding process, poor quality of heat treatment, mold, assembly, welding and other processes, poor assembly will cause poor fixation.

In addition, due to plating peeling, corrosion, bruising, plastic shell flash, cracking, rough processing of contact parts, deformation and other reasons, poor appearance, due to poor positioning locking fit size, poor processing quality consistency, total separation force is too Poor interchange caused by other reasons is also a common disease and frequent. These types of faults can generally be found and eliminated in time during inspection and use.

Application range of terminal products

3C product terminal

(1) Information products:

A. Personal PC desktop computer: internal power supply, uninterruptible power supply (UPS for short).

B. Industrial computer: internal motherboard and electromechanical control board.

C. Peripheral equipment: such as scanners, printers, copiers.

(2) Communication products

A. Wired transmission and terminal control systems and equipment: such as power supplies for electronic switches and connectors for telephone lines.

B. Wireless transmission and terminal-to-control systems and equipment: such as base station transmission equipment and power supplies for switches.

(3) Consumer electronics products: Mainly supply all kinds of video, audio and home appliance products in the world.

A. Video products include TV sets, VCRs and peripheral accessories for video recording.

B. Audio products include home audio, portable audio and car audio. Clothes dryer, microwave oven, oven, electric fan, electric heater, dishwasher, sports equipment, bathroom control system.

The future trend of consumer electronics products will combine audiovisual, communication and information technology, so-called 3C integration.

Terminals for electronic products

(1) Transmission system and transformer system in the power distribution system: used in power plants, transmission equipment, relay stations to factories, residential buildings, public buildings and industrial equipment, etc.

(2) Control system: mechanical equipment, elevators, automation equipment, etc. in various industries.

Transportation terminal

(1) It is widely used in the transmission of electric power and instrument panel signals of aircrafts, ships and various vehicles, electric vehicles.

(2) Electromechanical system of high-speed railway and subway.