Finding the right raw materials for Embossing thermal lamination film is a gamble GUANGDONG EKO FILM MANUFACTURE CO., LTD can’t afford to lose. We consider cost, manufacturing timelines, material properties, and many other factors. Therefore, deciding which materials to use is a cautious balancing act. We determine the best available materials by the following steps. The first step is to examine the material’s property specifications. This is especially useful for exploring and understanding new or unfamiliar material options. We can easily reduce the list of options by examining the baseline capabilities of one material and another. The next step is to define the priorities of Embossing thermal lamination film. We want to make the product perfect in a variety of ways, but in reality, most products have only one or two real selling points. Identifying what those are will suggest what type of materials should be used. The last step is to run production samples. Specific problems to look for include a series of material failure. Early detection and resolution of these problems can prevent them from becoming insurmountable or irreversible later in the process.

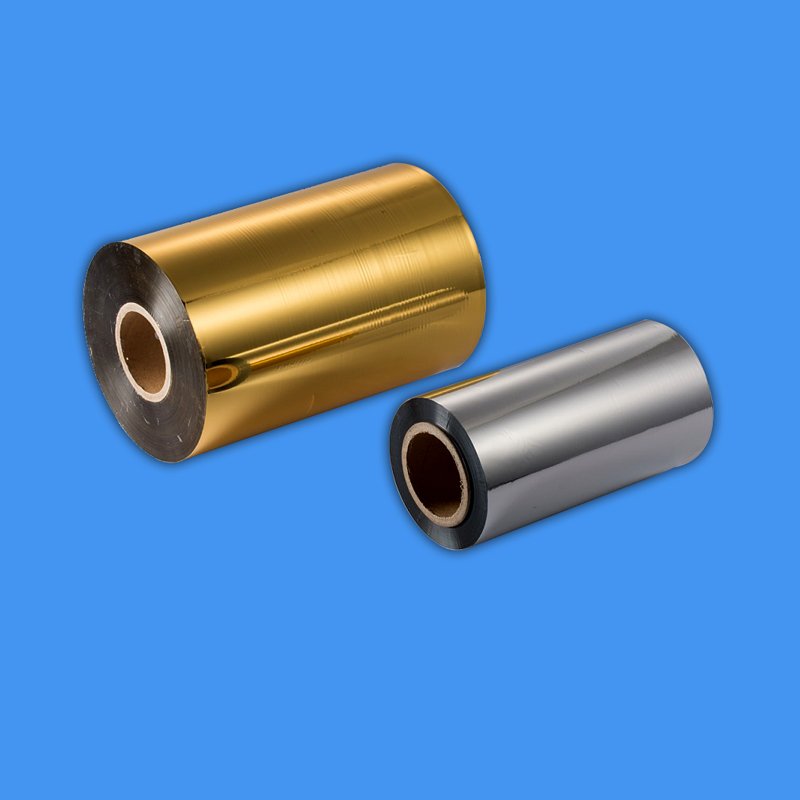

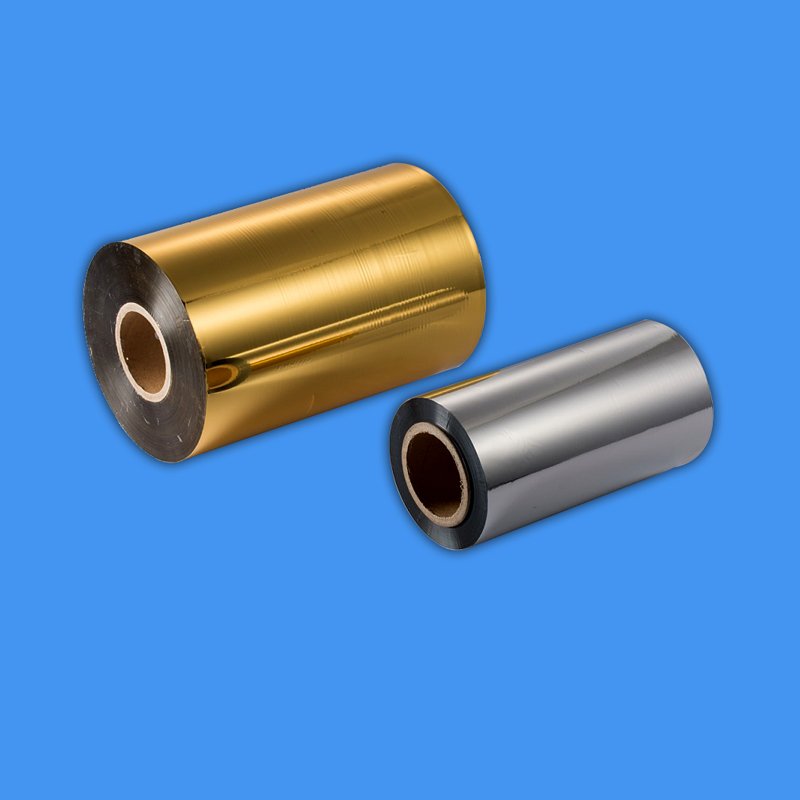

EKO is a model for Chinese anti scratch film manufacturers seeking to become well-known multinational brands. As one of EKO's multiple product series, thermal laminator series enjoy a relatively high recognition in the market. The product is designed to make digital work easier and more precise: tapping the keyboard is rarely ideal, and often cumbersome. Available Finishes are High Gloss and Non-Reflective Matte. Years of use of this product will definitely help manufacturers cut costs in energy, as well as reduce their carbon footprint of all production activities. EKO thermal lamination film has now reached the level of international standard.

Our motto is: “the business of business is relationships”, and we live that by working hard to satisfy each of our customers on a personal and professional level.