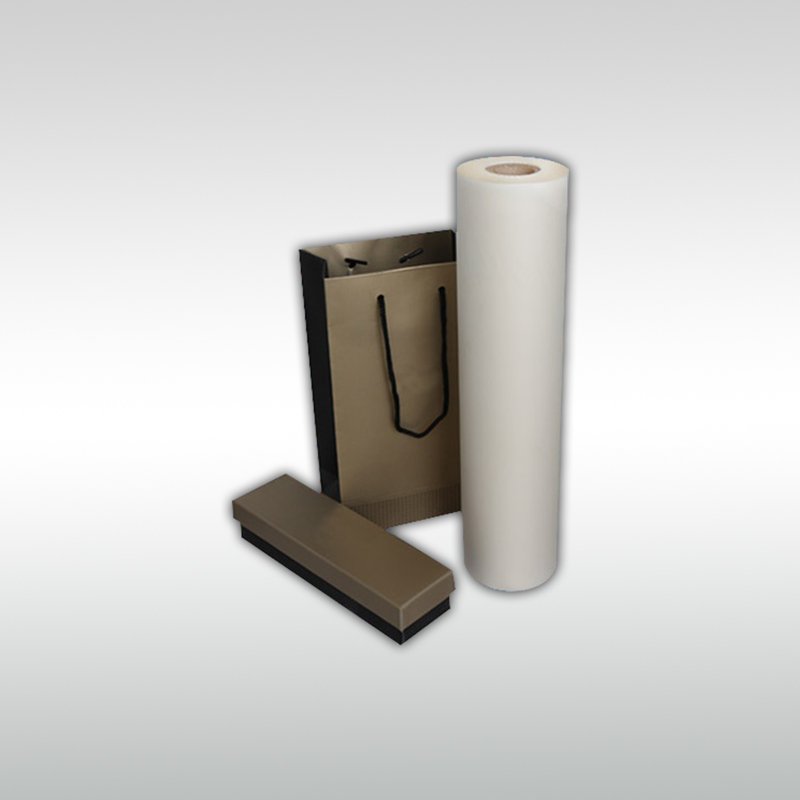

GUANGDONG EKO FILM MANUFACTURE CO., LTD has been engaged in research and development and production of pet thermal lamination film since its establishment. EKO has created a number of successful series, and super stick laminating film is one of them. This product features a fast and accurate reaction to the writing or drawing. Its high level of pressure sensitivity makes the lines flow smoother. EKO films have strong abrasion resistance. Because the product features high reliability, it reduces the risk of workers getting injured during production, which provides a safety guarantee. There are elastic components in the material that makes EKO films less breakable for better long-term use.

Our goal is that we aim to improve our products and solutions through innovations and smart thinking – to create more value at a reduced ecological footprint.