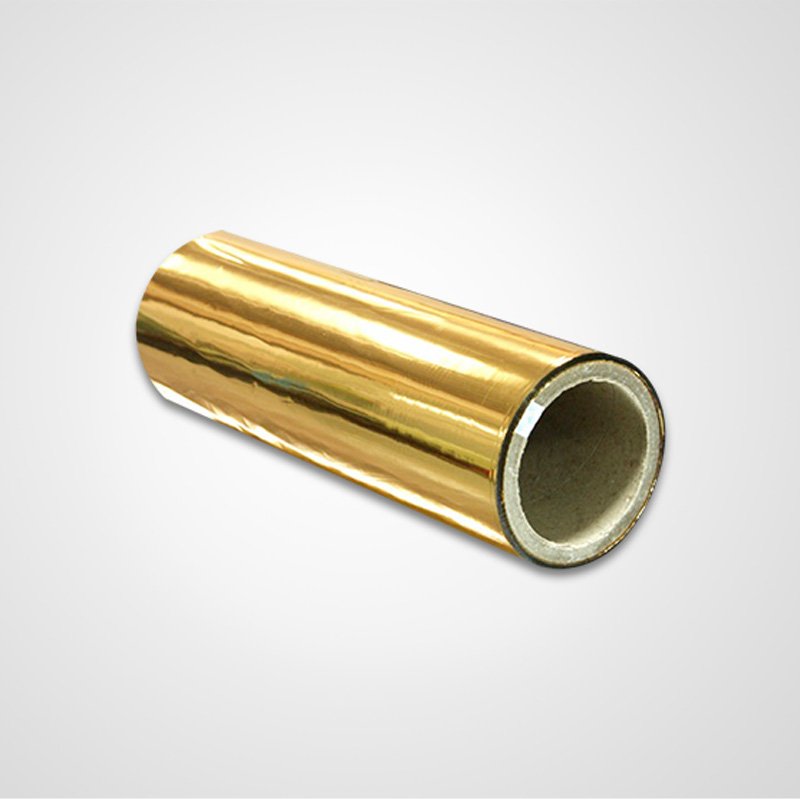

FSGUANGDONG EKO FILM MANUFACTURE CO., LTD is currently one of the very best in the soft touch lamination suppliers industry. Various in styles, EKO's holographic films manufacturers can meet the needs of different customers. FSEKO embossed plastic sheet will be scrutinized in an all-round way. Failure analysis will be conducted once it is finished, including fatigue failure, corrosion failure, toughness and brittle fracture, etc. EKO thermal lamination films are not easily breakable. The product can be easily adjustable. It is equipped with an adjustable strap such as laces or Velcro which allows for adjustment. our team thermal lamination films have amazing chemical resistance and excellent gloss.

our team never let you pay more than you need. Get an offer!