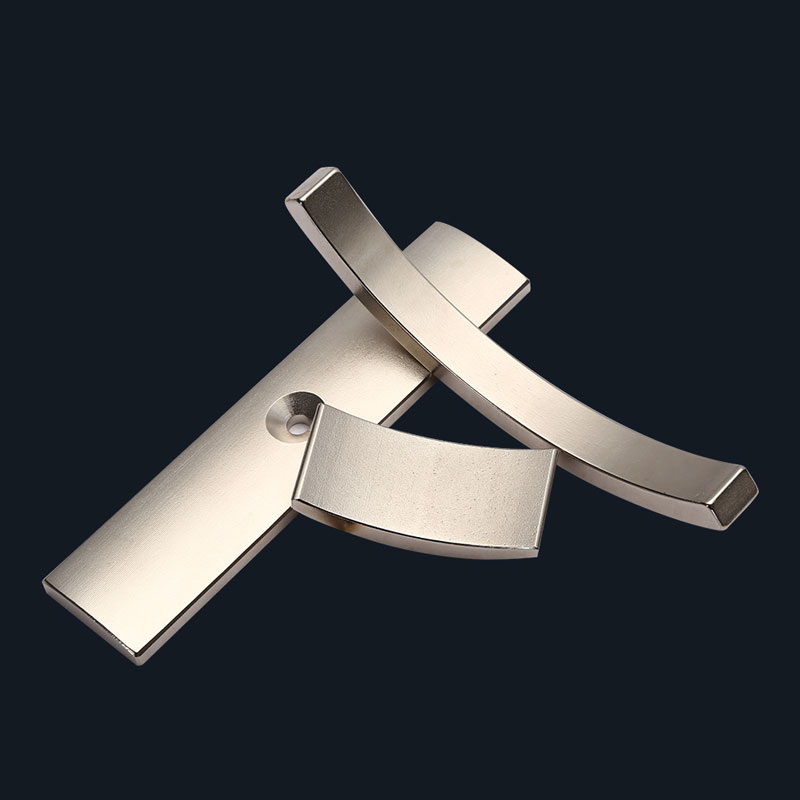

Xiamen XiaMen U-polemag Industry Ltd Ltd. is dedicated to the production and sales of coated neodymium magnets. We are now well recognized in the industry. The industrial magnets series is widely praised by customers. The manufacture of U-polemag trap magnet meets some important garment standards. They are the following standards: ISO, AATCC, ASTM, ANSI, BS, IWS, etc. Designed with a Ni coating, it has the best corrosion resistance performance. This product is able to retain its original appearance. Thanks to its protective surface, the effect of humidity, insects or stains will never destroy the surface. With excellent resistance to demagnification, it is perfect for both temporary or permanent use.

We value the sustainability of development. We will work to promote low-carbon and responsible investment by promoting socially responsible products. Inquire now!