Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

Torch SMT PCB smt assembly LED Lamp manufacturing pick and place machine LED600

1) Semi-Automatic LED Stencil Printer T1200LED

Specifications:

|

Model |

T1200LED |

|

Max print size of PCB board at X, Y direction |

1200*300mm |

|

Working stable size at X, Y direction |

1200*300mm |

|

Max frame size at X, Y direction |

1300*550mm |

|

Min frame size at X, Y direction |

330*370mm |

|

Range of micro-adjustment |

X, Y± 10mm, φ± 30° |

|

Accuracy |

±0.05mm |

|

Repeating |

±0.02mm |

|

Min pitch |

0.35mm |

|

Power supply |

AC220V single phase, 50 Hz |

|

Air pressure |

4-6kgf/cm² |

|

Dimension (MM) |

1850*890*1760 |

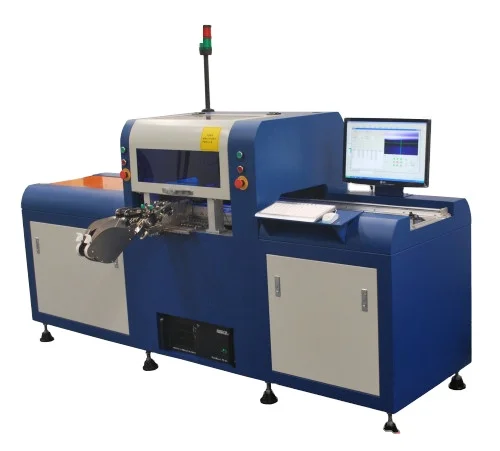

2) 2Head LED Pick and Place Machine LED600

Specification:

|

Model |

LED600 |

|

Mount head |

2 pcs |

|

Max circuit board size |

1200*350mm |

|

Max moving range |

X axis 1500mm, Y axis 360mm |

|

Max moving range of Z axis |

10mm |

|

Typical Mounting speed |

6000-6500 CPH |

|

Max mount speed |

7000cph |

|

Mount accuracy |

+/-0.1mm |

|

Position method |

Machinery position |

|

Component available |

0603and above SMD component and LED |

|

Programme method |

Automatic data import/ video study/ keyboard input |

|

Belt feeder |

8mm, 12mm, 16mm and 24mm |

|

Feeder num |

2 pcs of GF series feeder can be set |

|

Operation system |

WINDOWS XP |

|

Compressed air |

80 psi(0.5Mpa) |

|

Power supply |

220V,50Hz, 3 Kw |

|

Weight |

320kg |

|

Dimension |

2600*680*1500mm |

Features:

1. The first industry of special LED chip mounter using servo control system.

2. The first industrial using high precision ball screw drive LED chip mounter

3. The only one can reliable mount 20mm following SOP, diode, triode, SOT and more than 0603 apart (higher than 5m aluminum electrolytic capacitor)

4. Only a configuration own patent intelligent electronic feeder of LED automatic chip mounter

5. Only one complete the programming and placement of LED panel board

6. The only one to achieve off line programming feature LED placement machine.

7. The only one an video programming LED full automatically placement machine.

8. Powerful data input feature, can satisfy any format PCB data import.

9. The only one can reliable mount 0603 components LED full automatically placement machine.

10. The equipment with safe cover, protect the personal safe effectively, at the same time anti dust.

11. Can be configured more than 5 nozzle, softeware note you change nozzle automatically.

12. Actual mounting speed is 6000cph.

13. It can complete soft flexible light strip of (FPC) position and mount. (Optional)

Visual Camera

Max Place 12Pcs Feeder

transmission

3) 4Heating Zone Reflow oven TR340C

|

Heating part parameter |

TR340C |

|

Heating part parameter |

|

|

Temperature zone No |

4 heating zones (up 4, down 4) |

|

Cooling zone |

1 (up 1, down 1) |

|

Heating method |

Full forced hot air circulation |

|

Cooling system |

two group of cross-flow type whirlpool entrifugal Fan for cooling down evenly |

|

Temperature control system |

PC and Torch self-developed software control |

|

Temp control accuracy |

±2℃ |

|

Warm-up time |

<30 min |

|

Temp Range |

Room temp--360℃ |

|

Heating way |

Full hot air circulating convection |

|

Buil t-in automatic relay eating |

Avoid oven controller or motor damage due to |

|

|

|

Customer Visitng

Payment way

Share

Share

Customer Reviews total 0 items