Brand: |

none |

Address: |

China |

Min.Order: |

none |

Supply: |

none |

Valid until: |

Long Term |

Product Details

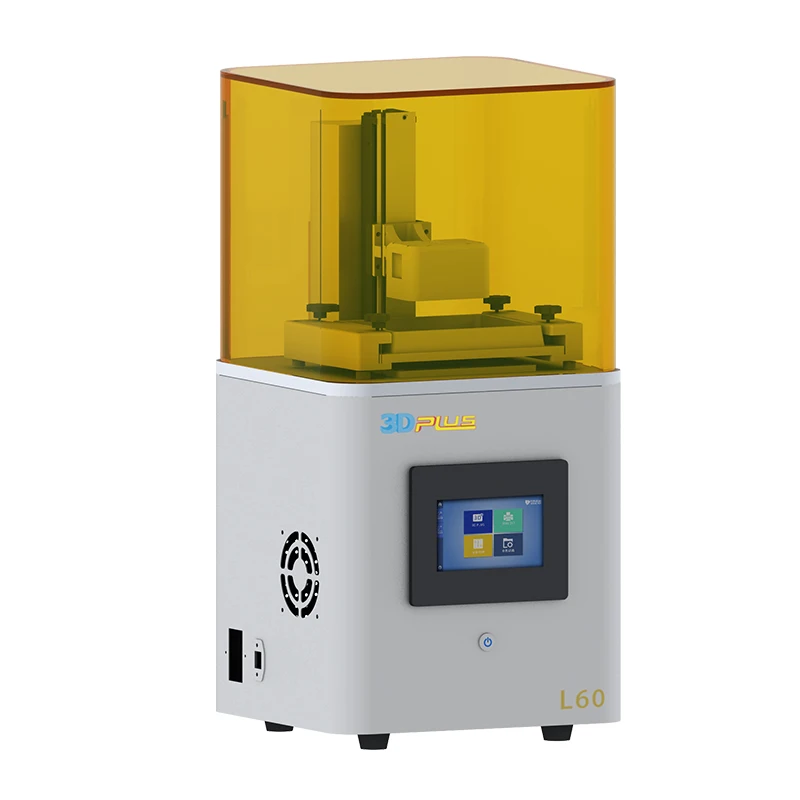

2018 New DLP 3D printer, 3D dental printer, 3D Jewelry printer with LED light life 20000 hours

Plus 6 (L60) is an Industrial Grade High Precision Printing Machine 3D for Jewelry Resin models, which can print big-size moldings with high precision and great-smoothness surface quality. Very simple and easy operation, and it can assist small casting device to make jewelries in small batch and individuation.

Parameter List:

2018 New DLP 3D printer, 3D dental printer, 3D Jewelry printer with LED light life 20000 hours

High Precision Printing Machine 3D for Jewelry Plus 6 has adopted specialized high-definition projection optical engine, and the definition is WXGA (1280×800). It has high uniformity of illumination, which can ensure stable molding at each location of molding plane. Highly stable LED UV light source is used, and the service life can reach 20000 hours, which can ensure reliable molding during the printing process. The molding size is bigger, which can reach 68(X)×42(Y)×100(Z)mm; multiple models or big-size model can be printed, and 15 models can be printed every 3 hours. The X/Y molding precision is 53μm, the thickness of Z axis layer is 0.025-0.05mm, and a height of 6-12mm(Max is 20mm) can be printed every hour.

Specifications

1. Industrial Grade integrated machine, very stable, it can ensure the printing quality;

2. It supports STL/SLC multi-format, which does not require connecting with computer, and it can print offline;

3. Color LCD touch-sensitive screen module, it supports one-key switch between Chinese, English and Thai;

4. Super resin VAT, long service life, big resin VAT has more stable molding;

5. Multiple materials can satisfy different application requirements, which can perfectly match the equipment.

First:

Machines have equipped the LED UV Light Source, the LED advantages are high service life (≥20000 hours), very stable and even, have no dead corners (which compares with UHP Light Source ). So it can keep perfect same precision at each position,each dots, each corner in every layer.

Second:

All machines have passed high standards of inspection, calibration and testing. In our concept, quality is the first, service is the second, price is the last.

Third:

Machines have adopted marble as its working platform. Marble has marvelous advantage in resisting heat and cold temperatures. EnvisionTec hasnot even taken such technology because of the high cost of Marble.

The Printing Z axis has great control power on printing precision. Our machines have equipped the integrated modular which has high stable feature from Taiwan, not like others who use iron line and steel prop.

Forth:

The resin tray has the service life for 2 - 3 months, which isnot the longest lift , but the price is very cheap. German Resin tray can be used for half of year, but its price is 3-4 times of ours. DWS Resin tray can be used for only 2-3 weeks life, but its price is also much higher than ours.

Fifth:

The DC power system has adopted from Taiwan Mean Well company, which is one of the leading brand manufacturers of standard exchangeable power supplies in the world. The controllers and electronic components are durable enough for 24/7 printing requestments.

3D Plus Software

3D Plus software is independently reseached and developed by our software engineering team. Servicing for clients' using and summarizing clents' experience, 3D Plus software can print high precision size and great smoothy surface, with easy-to-use feature(only 3 steps to print).

We also provide you the design software which can easily add supports and type setting for your 3D designing.

With the rapid development of 3D Printing Technology, the 3D Printer machines and equipments are growing maturely, in the future, the King Point of 3D Printing Technology is Printing Material. 3D Plus has well known this King Point since it was established.

3D Plus has developped mature directly casting resin, which has the features as :

Great combustible performance

Perfect resisting thermal expansion

Great optical penetration performance

So its finished-printing resin models have great smooth surface and perfect precision.

From the very beginning to now, 3D Plus Always keeps its 3D printing technology closely contacting with Jewelmen and Jewellery Industry.

Our 3D printing centre in Guangzhou keeps printing every day. We also keep our Jewellery factory printing every day and casting every day. This can perfectly verify our 3D printing technology, what's more, it can be continously enhanced by the summarized experience from Jewelry productions and improved by the new requestments from Jewelry productions.

Due to the mature pratical application, skilled 3D printing engineering team, experienced Jewellery technicians and Jewelmen (Our boss has run Jewellery factory for more than 15 years), less than 2 years, 3D Plus 3D Printers become the first choice and best example of DLP 3D printers for Jewellery industry.

We can provide overall revolutionary solutions to the jewelry industry. We provide DLP 3D Printer, photosensitive resin, casting equipment and process. The printing model has great surface quality and high production precision, which can print small features and micro structure, so that the model can perfectly restore the designer's 3D data of jewelry. We can provide professional instruction and guidance, as well as revolutionary solution to the whole production line of jewelry production.

1. Pre-sale service

you can send your own Jewelry CAD drawing files to us by email, we will print and cast moldings for you free off charge, to test our pinter's precision and formation. We can take pictures to show you the moldings and also can send them to you by DHL with the DHL fee at your site.

2. In-sale service

We will provide you complete manuals in word files and vedio files , to tell you how to operate and maintain our 3D plus printer step by step.

And also we accept your staff to come to our place for training.

3. After-sale service

We have English engineers to fly to your place for training your staff . And you can also find our after-sale service by telephone and internet in 24/7 .

4. Warranty

One year for whole machine except Material tray and Resin. Two years for LED light source.

Agency Service

We now have Exclusive Agencies in 18 countries and regions, contact us for your local partner:

Totus, locates in Wujin National High-tech Industrial Development Zone, Changzhou City, Jiangsu Province, which is the core district of Yangtze River delta area, very near from the beautiful West Tai Wake and innovative Changzhou Science & Education Town, at the Changzhou south exit of S38 Chang-He Expressway. It focuses on the industries of Jewelry, dental medicine, education, building, rapid production, and provides them the professional 3D printing machines and services, and also has the skilled R&D team and well trained after-sales service team.

It provides clients the high-precision and high efficient 3D printing solutions with professional R&D strength, ensure the stability of 3D printing machines and printing material with excellent producing quality, make sure to solve the machine failures and clients' doubts with fast after-sale service.

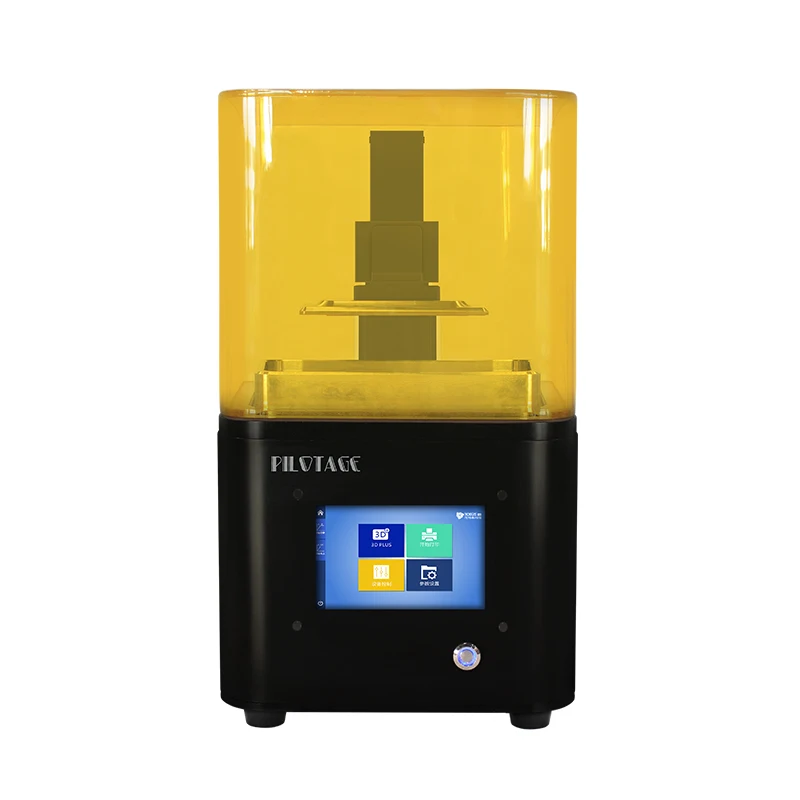

3D Plus is Totus' famous brand, now it is widely used in Jewelry industry, toy models making, education and training system, and so on. Its 3D printers have adopted the DLP (Digital-Light Processing) digital photo-curing rapid molding principle. The high-resolution digital optical engine is used to project light of special band to cure liquid photopolymer, and conduct photo-curing layer by layer. During curing of each layer, sheet curing is realized through image similar to slide, so the molding has high speed and precision, which has significant advantages on the aspect of material property, details and surface smoothness.

Share

Share

Customer Reviews total 0 items